Using the Yaskawa Motors

SGD Servopack Manual.pdf (7MB)

Servopack

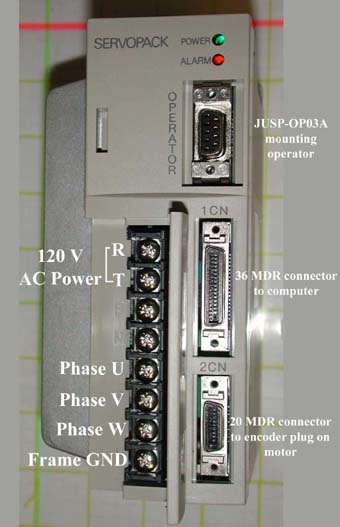

The SGM-02B312 motor that we have is 100V, 200W and works together with the Yaskawa Servopack which acts as a controller/amplifier. Servopacks come in two modes: speed/torque referencing, and position referencing. The majority of the Servopacks that we have are speed/torque and have the model number SGD-02BS (the last S for speed). Position referencing Servopacks

are SGD-02BP. The following is a picture of the Servopack.

OPERATOR can connect to a PC or a Yaskawa Digital Operator. The following functions are performed with the operator: user constants settings, run command, status display, and alarm display. We DO NOT SEEM TO have the operator that can directly mount onto the Servopack (JUSP-OP03A).

However, the PC-based program is supposed to be able to do all the same operations and more. It is called SVMON and is archived here on Yaskawa's site

1CN receives an analog or pulse train input that can control the motor. The connector is a 36-contact Mini D Ribbon (MDR) connector made by 3M.

2CN connects to the encoder outputs from the motor via the encoder cable. The connector is a 20-contact MDR connector made by 3M.

R, T on the terminal strip connect to 120V AC power from the wall.

U, V, W, GND on the terminal strip connect to the motor phase inputs via the motor cable to determine the motion of the motor.

1CN Connector

The following figures show the front and back of the 1CN connector. The pins are numbered on the back view.

|

|

| Front | Back |

The following table shows the layout of the pins on the 1CN connector. Servo ON is pin 14.

| 1 | Torque Reference Input | 19 | PG Output Signal 0V | |

| 2 | Torque Reference Input 0V | 20 | PG Output (Phase-A) | |

| 3 | Speed Reference Input | 21 | PG Output (Phase-A) | |

| 4 | Speed Reference Input 0V | 22 | PG Output (Phase-B) | |

| 5 | 23 | PG Output (Phase-B) | ||

| 6 | 24 | PG Output (Phase-C) | ||

| 7 | Brake Interlock Signal Output | 25 | PG Output (Phase-C) | |

| 8 | Speed Coincidence Signal Output | 26 | ||

| 9 | TGON Signal Output | 27 | ||

| 10 | Common 0V to pin 7,8,9 | 28 | ||

| 11 | Forward Current Limit ON Input | 29 | ||

| 12 | Reverse Current Limit ON Input | 30 | Alarm Code Output | |

| 13 | +24V External Power Input | 31 | Alarm Code Output (open collector output) | |

| 14 | Servo ON Input | 32 | Open Collector Output | |

| 15 | P-Drive Input | 33 | Alarm Code Output Common 0V | |

| 16 | Forward Prohibit Input | 34 | Servo Alarm Output | |

| 17 | Reverse Prohibit Input | 35 | Servo Alarm Output | |

| 18 | Alarm Reset Input | 36 | Frame Ground |

Encoder Cable (2CN)

The following figures show the front and back of the 2CN connector.

|

|

| Front | Back |

The following table shows the layout of the pins on the 2CN connector.

| 1 | PG Power 0V | 11 | ||

| 2 | PG Power 0V | 12 | ||

| 3 | PG Power 0V | 13 | ||

| 4 | PG Power 0V | 14 | PG Input C-Phase | |

| 5 | PG Power +5V | 15 | PG Input C-Phase | |

| 6 | PG Power 0V | 16 | PG Input A-Phase | |

| 7 | Rotating Direction Input | 17 | PG Input A-Phase | |

| 8 | 18 | PG Input B-Phase | ||

| 9 | 19 | PG Input B-Phase | ||

| 10 | 20 | Frame Ground |

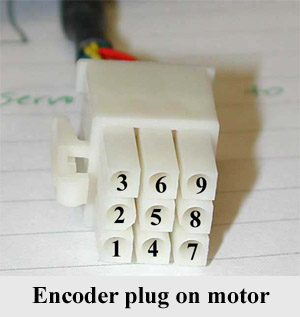

The 20-contact MDR connector is attached to 9 conductor, 22 AWG, fold shielded cable. On the other end of the cable is an AMP 9 pin MATE-N-LOK connector cap that plugs into the encoder plug on the motor. The following figures show the ends of the encoder cable and the encoder plug on the motor.

|

|

Here is a table laying out what each pin is connected to on the encoder plug.

Incremental encoder connection

|

Encoder Plug Pin # |

|

Color (on motor) |

2CN pin # |

|

1 |

Channel A output |

Blue |

16 |

|

2 |

Channel A output |

Blue/Black |

17 |

|

3 |

Channel B output |

Yellow |

18 |

|

4 |

Channel B output |

Yellow/Black |

19 |

|

5 |

Channel C output |

Green |

14 |

|

6 |

Channel C output |

Green/Black |

15 |

|

7 |

0V (Power supply) |

Gray |

1,2,3 |

|

8 |

+5V (Power supply) |

Red |

4,5,6 |

|

9 |

FG (Frame Ground) |

Orange |

20 |

Motor Cable

The connector that fits onto the motor plug is a AMP 4 pin MATE-N-LOK connector cap. The cable is a 4 conductor, 20 AWG, foil shielded cable. The other end is connected to 4 ring tongue terminals which screw into the Servopack terminal strip (U, V, W, GND). The following figure and chart show which pin corresponds to which motor phase.

|

|

Motor Connection

| Motor Plug Pin # | Color (on motor) | |

| 1 | Phase-U | Red |

| 2 | Phase-V | White |

| 3 | Phase-W | Blue |

| 4 | FG (Frame Ground) | Green |

Parts

Here is a list of vendors and part numbers to buy all of the cables and connectors necessary to get the motor and Servopack working together.

| Vendor | Part number |

Description | |

| Encoder Cable (2CN) | Digi-key | A25699-ND |

AMP 9 Pos mini universal MATE-N-LOK connector cap housing |

| Digi-key | 170365-1-ND | AMP mini universal MATE-N-LOK socket contacts. 26-22 AWG | |

| Newark | 03F6197 | Multiconductor cable, foil shielded. 9 conductors, 22 AWG, 100 ft | |

| Newark | 90B3949 | 3M 20 contact 0.050" Mini D Ribbon (MDR) solder plug connectors | |

| Allied Electronics | 618-0034 | 3M 20 contact MDR Junction shells | |

| Motor Cable | Digi-key | A25572-ND | AMP 4 Pos mini universal MATE-N-LOK connector cap housing |

| Digi-key | 170366-1-ND | AMP mini universal MATE-N-LOK socket contacts. 18-22 AWG | |

| Newark | 02F8167 | 4 conductor cable, foil shielded, 20 AWG, 100 ft. | |

| Newark | 93F4913 | Ring Tongue terminals, 22-18 AWG, stud size 8 | |

| 1CN connector | Newark | 90B3954 | 3M 36 contact 0.050" MDR solder plug connectors |

| Allied Electronics | 618-0013 | 3M 36 contact MDR Junction shells (note: shell is optional and may be undesired) | |

| Power cord | Newark | 19C1608 | 3 conductor Power supply cord, 18 AWG, SJT |