Difference between revisions of "NU32: Using the MCP42X1 SPI Digital Potentiometer"

| Line 6: | Line 6: | ||

A potentiometer is useful in a variety of circumstances when a variable resistance is needed. A digital potentiometer provides a variable resistor that can be controlled from a microcontroller. Because the MCP42X1 is a 7-bit device, there are 2^7 = 128 possible resistance "steps". By communicating with the IC over SPI, we can choose what step (and thus, resistance) the potentiometer is set at. |

A potentiometer is useful in a variety of circumstances when a variable resistance is needed. A digital potentiometer provides a variable resistor that can be controlled from a microcontroller. Because the MCP42X1 is a 7-bit device, there are 2^7 = 128 possible resistance "steps". By communicating with the IC over SPI, we can choose what step (and thus, resistance) the potentiometer is set at. |

||

[[ |

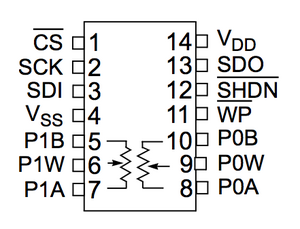

[[image:mcp42x1.png|thumb|300px|MCP42X1 Pinout|right]] |

||

The resistance across the PxB and PxW (the wiper) is governed by |

The resistance across the PxB and PxW (the wiper) is governed by |

||

Revision as of 11:52, 14 July 2012

The MCP42X1 is a 7-bit dual digital potentiometer. It is available in total resistance options of 5, 10, 50 and 100 kOhm. It is controlled using SPI communication and a digital output (CS). It has two independent potentiometer channels, each with its own wiper.

Overview

A potentiometer is useful in a variety of circumstances when a variable resistance is needed. A digital potentiometer provides a variable resistor that can be controlled from a microcontroller. Because the MCP42X1 is a 7-bit device, there are 2^7 = 128 possible resistance "steps". By communicating with the IC over SPI, we can choose what step (and thus, resistance) the potentiometer is set at.

The resistance across the PxB and PxW (the wiper) is governed by where the 5kOhm comes from the total resistance of the pot, depending on the model. The value N is the setting of the pot between 0 and 127.

The pot requires four communication pins from a microcontroller: SPI CLK, SDO, SDI, and one digital output. The pot is powered with 3.3V. This model is a dual pot chip, meaning it has two completely independent potentiometer channels in the same IC, referred to as Pot 0 and Pot 1, respectively.

Details

Example schematic when communicating with the NU32, using SPI channel 1:

- Pot 1-CS -----> F3

- Pot 2-SCK -----> D10

- Pot 3-SDI -----> D0

- Pot 4-VSS -----> GND

- Pot 5-P1B -----> P1+

- Pot 6-P1W -----> P1-

- Pot 7-P1A -----> NC

- Pot 8-P0A -----> NC

- Pot 9-P0W -----> P0-

- Pot 10-P0B -----> P0+

- Pot 11 -WP -----> NC

- Pot 12 - SHDN -----> 3.3v (this pin is inverse-shutdown, so we keep it high)

- Pot 13-SDO -----> C4

- Pot 14-VDD -----> 3.3v

The resistance across PXB and PXW is what changes, labeled above as Px+ and Px-.

Library Functions

MCP42X1.c contains the following functions:

- void SPI_initPots() : sets up SPI channel 1, and CS pin

- void incPot(int pot_num) : will increment wiper by one step

- void decPot(int pot_num) : will decrement wiper by one step

- int setPot(int pot_num, int wiper) : sets the given pot to specific wiper value (0 - 127), returns success boolean

- int readPot(int pot_num) : reads the current wiper setting from the pot, returns (0 - 127)

- void testPots() : runs tests of setting, incrementing, decrementing, and reading both channels to confirm pots are working properly

Sample Code

Initialize and clear the LCD:

LcdInitialize();

LcdClear();