Difference between revisions of "Attaching to a shaft"

| Line 5: | Line 5: | ||

* [http://www.nmbtc.com/bearings/engineering/fitting.html Press fit or interference fit]; see also the [http://en.wikipedia.org/wiki/Interference_fit wikipedia page] (note: be careful not to apply axial press forces large enough to damage the motor; the shaft should be supported [clamped] during the press to avoid this) |

* [http://www.nmbtc.com/bearings/engineering/fitting.html Press fit or interference fit]; see also the [http://en.wikipedia.org/wiki/Interference_fit wikipedia page] (note: be careful not to apply axial press forces large enough to damage the motor; the shaft should be supported [clamped] during the press to avoid this) |

||

* [http://en.wikipedia.org/wiki/Set_screw Set screws] |

* [http://en.wikipedia.org/wiki/Set_screw Set screws] |

||

[[Image:setscrew.jpg|120px|thumb|A rigid coupler that couples two shafts, possibly of different diameter, using one set screw for each.]] |

[[Image:setscrew.jpg|120px|thumb|A rigid coupler that couples two shafts, possibly of different diameter, using one set screw for each.]] To get good holding torque with set screws, they have to be clamped down hard on the shaft, which can damage the shaft. For larger holding torques, a better option is to have a friction fit around the entire shaft. This can be achieved by compliant elements that squeeze onto the shaft as one or more screws are tightened. |

||

To get good holding torque with set screws, they have to be clamped down hard on the shaft, which can damage the shaft. For larger holding torques, a better option is to have a friction fit around the entire shaft. This can be achieved by compliant elements that squeeze onto the shaft as one or more screws are tightened. |

|||

<br clear=all> |

<br clear=all> |

||

* Split clamp [[Image:split-clamp.gif]] [[Image:splitclamp2.jpg]] |

* Split clamp [[Image:split-clamp.gif]] [[Image:splitclamp2.jpg]] |

||

Revision as of 06:07, 21 June 2010

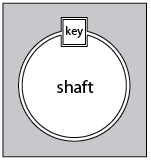

There are many ways to attach to a shaft (e.g., a motor shaft). Below are a few examples.

- Press fit or interference fit; see also the wikipedia page (note: be careful not to apply axial press forces large enough to damage the motor; the shaft should be supported [clamped] during the press to avoid this)

- Set screws

To get good holding torque with set screws, they have to be clamped down hard on the shaft, which can damage the shaft. For larger holding torques, a better option is to have a friction fit around the entire shaft. This can be achieved by compliant elements that squeeze onto the shaft as one or more screws are tightened.

As the nut is tightened, the inner diameter shrinks, clamping on to the shaft, and the outer diameter grows, clamping on to the inside diameter of the component.

Typically two cylindrical pieces are put around the shaft. As they are screwed together, an inner taper on one of the pieces clamps on to the shaft.

- Epoxy

Some companies that provide shaft couplings:

- Fenner Drives

- McMaster-Carr (split collars, shaft couplers, trantorque bushings)

- Stock Drive Products (shaftloc and other couplings)

- Lovejoy

- Ringfeder