Difference between revisions of "Continuously Variable Transmission"

DavidEvitt (talk | contribs) |

DavidEvitt (talk | contribs) |

||

| Line 79: | Line 79: | ||

<tr><td>1/2"-10 Acme threaded rod</td><td>98935A823</td><td>1</td><td>[http://www.mcmaster.com McMaster]</td><td>$7.12</td></tr> |

<tr><td>1/2"-10 Acme threaded rod</td><td>98935A823</td><td>1</td><td>[http://www.mcmaster.com McMaster]</td><td>$7.12</td></tr> |

||

<tr><td>Bronze 1/2"-10 Acme nut</td><td>1343K134</td><td>2</td><td>[http://www.mcmaster.com McMaster]</td><td>$72.24</td></tr> |

<tr><td>Bronze 1/2"-10 Acme nut</td><td>1343K134</td><td>2</td><td>[http://www.mcmaster.com McMaster]</td><td>$72.24</td></tr> |

||

<tr><td> |

<tr><td>Misc. fasteners and stock</td><td>-</td><td>-</td><td>Shop</td><td>-</td></tr> |

||

</table> |

</table> |

||

Revision as of 05:19, 21 March 2008

Team members

- David Evitt: Mechanical Engineering, Class of 2009

- Tyler Miller: Electrical Engineering, Class of 2009

- Raymond Mui: Mechanical Engineering, Class of 2008

Overview

The goal of this project was to create an electronically controlled, belt-driven, continuously variable transmission (CVT).

A CVT is a type of transmission that can smoothly transition between gear ratios. This can be achieved in a variety of ways. We chose to use movable conical pulley halves and a v-belt, similar to the CVTs commonly found on snowmobiles. The conical faces of the pulley halves create a valley that the belt rides in. The belt wedges as far down in the valley as possible, so the distance between the pulleys controls what radius the belt rides at. As the pulley halves move together it forces the belt out of the valley to run at a larger radius, if the pulley halves move further apart the belt will fall down the valley to run at a smaller radius. Two sets of pulley halves work together and move simultaneously to form the transmission. One pulley moves to control the gear ratio, the other pulley adjusts to maintain belt tension. For example if the input pulley halves begin far apart and the output pulley halves begin close together the transmission is in low gear. As the input pulley halves move together, the output pulley halves move apart to maintain constant belt tension, as illustrated in the figure. This motion is a smooth shift from low to high gear, as shown in the video.

A variable ratio transmission is a useful device. With a fixed gear ratio, the output speed is a constant multiple of the input speed. This means that as the output speed increases the input speed must also increase. In a vehicle application this means that the engine speed changes greatly as the vehicle accelerates. If the gear ratio is variable the input can remain at constant speed as the output speed increases. In vehicle terms, the engine speed can be held constant while the vehicle accelerates. This is helpful because the engine can always operate at peak power for maximum acceleration, or at maximum efficiency. The Formula SAE team is working toward implementing a CVT on their next competition vehicle to take advantage of this property. This proof of concept prototype is the first step towards that goal.

More about CVTs can be found in the further reading section.

This wiki page documents the mechanical and electrical systems, the code, and our reflections on the project.

Mechanical Design

System Operation

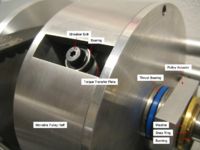

Our CVT shown to the right was constructed in the Ford Building machine shop. It consists of two pulley assemblies. Each pulley assembly has one half fixed to the shaft, the other half is able to translate along the shaft, but is prevented from rotating by the torque transfer plate, which is fixed to the shaft. The movable pulley slides on bushings and rolls on the torque transfer plate bearings so it is free to move, even under load. The position of the movable pulley is determined by the pulley actuator, which is controlled by the lead screw. Three Pittman GM8224 motors actuate the system. One spins the input shaft, the other two control the lead screws setting pulley position.

Pulley Control

The input and output pulleys serve different functions which are reflected in the control hardware. The input pulley sets the gear ratio, the output pulley maintains belt tension. The input pulley actuation system is rigid, enforcing the pulley position commanded by the controller. The output actuation system has compliance built in with springs, allowing flexibility to maintain a near constant belt tension.

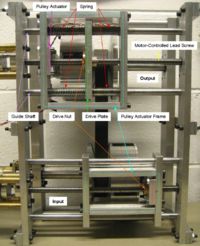

The control motors turn a lead screw that pushes a drive nut. That drive nut slides the actuator frame along the guide shafts, which adjusts the pulley actuator, controlling pulley position. The wide actuator frame is necessary to resist the moment from the cantilever pulley actuator and not bind. In the case of the output actuator, the drive plate floats in the actuator frame on springs. As the gear ratio changes the output lead screw control motor turns in the proper direction compressing the springs, which in turn applies belt tension, until the limit switch is depressed at which point the lead screw stops. As the input pulley continues to shift the springs keep adjusting the position of the output pulley until the limit switch opens again. The lead screw then moves until the switch is again closed. The net result is that the output control screw moves in small steps and the spring force keeps even belt tension.

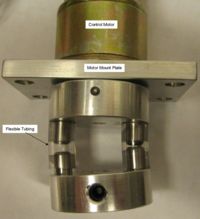

Flex Coupling

Simple flex couplings to connect the motor and control shafts were developed for this prototype. They consist of flexible tubing pressed over matching pins as seen in the figure at right and have the following benefits:

- Significant misalignment in any direction can be accommodated.

- The stiffness of the joint can be adjusted with the number of pin pairs and tubing properties.

- They provide overload protection. At a certain torque the tubing segments will rip or pop of the pins to break free.

The design can readily be adapted to other applications and may be useful for other student projects as a low cost option.

Part List

| Part | Part No. | Qty | Vendor | Price (Total) |

|---|---|---|---|---|

| Pittman 24V DC motor | GM8224 | 3 | Lab | - |

| Shoulder Screw | 91259A535 | 8 | McMaster | $6.56 |

| 1/4" bearing | 60355K33 | 8 | McMaster | $39.84 |

| 3/8" bearing | 60355K35 | 4 | McMaster | $20.68 |

| 3/4" bearing | 60355K38 | 4 | McMaster | $33.40 |

| Thrust bearing | 6655K22 | 2 | McMaster | $10.96 |

| SAE 841 1/2" bushing | 6391K212 | 10 | McMaster | $6.50 |

| SAE 814 3/4" bushing 1" long | 6391K259 | 2 | McMaster | $2.98 |

| SAE 814 3/4" bushing 2" long | 6391K269 | 2 | McMaster | $8.40 |

| 1/2" steel drive shaft | 1346K17 | 4 | McMaster | $25.84 |

| 3/4" steel drive shaft | 1346K31 | 4 | McMaster | $19.12 |

| spring | 9620K57 | 4 | McMaster | $17.68 |

| 1/2"-10 Acme threaded rod | 98935A823 | 1 | McMaster | $7.12 |

| Bronze 1/2"-10 Acme nut | 1343K134 | 2 | McMaster | $72.24 |

| Misc. fasteners and stock | - | - | Shop | - |

Electrical Components for the CVT

Circuits

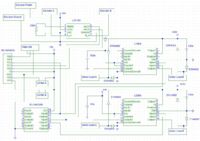

To control the two Pittman motors, we used quadrature decoding to keep track of the counts. We used LS7183 chips found in the Mechatronics lab instead of LS7083s.

A schematic of the circuit is presented to the right.

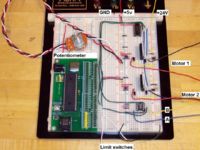

The completed circuit setup can be viewed on the right.

Programming

The PIC reads an input voltage reading from the potentiometer from pin RA0. This value is compared to the upper and lower bounds governing the pulley's widths to determine whether the pulley needs to move farther or closer together. We then use quadrature decoding to keep track of the counts, thereby tracking the number of rotations. With the 10:1 gear ratio (10 revolutions per 1 in of travel), we also know how far it has moved. We modified the quadrature hardware code available from the example code page to perform this task.

The code for the entire setup can be found here.

Results

Unfortunately, due to technical errors and circuit component failure (namely frying three PICs along with other melted components), we were not able to implement the PIC control for the two pulleys. To demonstrate the apparatus, we implemented manual control of the two Pittmans using switches to control the pulley widths. The demonstration showed that the system functions well mechanically. Manual control illustrated the need for feedback control for this system, as the transitions from low to high gear required a nonlinear shift in the pulley radii.

With further work on the circuits and controls, we hope to get the CVT working as intended with PIC control.

Further Reading

More details regarding the operation of a CVT, along with various forms of CVTs