Difference between revisions of "Programmable Stiffness Joint"

EricNickel (talk | contribs) |

EricNickel (talk | contribs) |

||

| Line 32: | Line 32: | ||

The rotational stiffness of a joint is defined as the moment required to cause a given angular rotation. |

The rotational stiffness of a joint is defined as the moment required to cause a given angular rotation. |

||

===Fundamental |

===Fundamental Equation=== |

||

Based upon the diagram at right, the following variables are defined for these equations: |

Based upon the diagram at right, the following variables are defined for these equations: |

||

| Line 43: | Line 43: | ||

There are two major aspects to consider for rotational stiffness: |

|||

Give full description of the theory here |

|||

First, a linear spring requires a constant force to change the spring length. This is described by Hook's Law (shown below) where F is the force applied to the spring, x is the change in length of the spring (in this case, it will only be extension), and k is the stiffness of the linear spring. |

|||

F = k * x |

|||

<br clear=all> |

<br clear=all> |

||

Revision as of 12:13, 19 March 2008

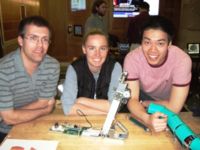

Team Members

- Amanda Care (Senior in Mechanical Engineering, Northwestern University)

- Eric Nickel (Graduate Student in Biomedical Engineering, Northwestern University, BS in Biomedical Engineering from the Milwaukee School of Engineering)

- James Yeung (Junior in Electrical Engineering, Northwestern University)

Overview

The "Programmable Stiffness Joint" is a device which is able to internally modify the rotational stiffness of a simple pivot joint. It is intended to serve as a proof-of-concept for future work in developing a model for determining the respective damping and stiffness components of the human ankle joint over the able-bodied gait cycle. This information in turn will permit prosthetists and rehabilitation engineers to design and fit prostheses better designed for the user's gait kinetics, which in turn should produce more natural gait kinematics.

The goal of our project is: To develop a working model of a device which is able to control the stiffness of a joint in such a manner as to mimic the motion of a human ankle joint. The user is able to select a stiffness level and the device will adjust itself to provide the specified level of rotational stiffness. The set-point of the joint will remain constant for all stiffnesses.

This is how it works: A linear coil extension spring has a constant stiffness within its elastic extension limit. As the location of the insertions of the spring on the base and rotating member change position, the amount of spring extension experienced for a given angular change of the rotating member will vary, as will the torque produced by the spring tension. These variations are taken advantage of to produce widely different stiffnesses from a single linear extension coil spring. The user can either select a pre-scaled stiffness setting or manually control the insertion point on the rotating member to vary the joint's rotational stiffness.

We will discuss:

- Stiffness theory and the conceptual framework which guided the design of the device

- Mechanical design and function of the device

- Electrical design and function of the device

- PIC control and the software developed to control the device

- Results of final testing

- Future work and lessons learned

Stiffness Theory

The rotational stiffness of a joint is defined as the moment required to cause a given angular rotation.

Fundamental Equation

Based upon the diagram at right, the following variables are defined for these equations:

- L1 = The distance from the pivot point to the "heel" insertion point of the linear spring on the base plate

- L2 = The distance from the pivot point to the "shank" insertion point of the linear spring on the rotating element

- L3 = The distance between the two insertion points

- h = The height of the insertion point on the rotating member for a given angle and L2

- a = The horizontal component of the position of the insertion point location on the rotating member for a given angle and L2

- theta = The angle of the rotating member with respect to the vertical (perpendicular to the base plate)

There are two major aspects to consider for rotational stiffness:

First, a linear spring requires a constant force to change the spring length. This is described by Hook's Law (shown below) where F is the force applied to the spring, x is the change in length of the spring (in this case, it will only be extension), and k is the stiffness of the linear spring.

F = k * x

MATLAB Simulation

Simulations of the above theory in MATLAB produced the following results.

MATLAB Code

Insert MATLAB code here with appropriate comments.

Mechanical Design

The primary structural components used in this device are:

The sensors/actuators used are:

Electrical Design

The primary components used in this circuit are:

- Controller (PIC)

Code

Results

Our resulting design:

Reflections

- Move circuitry to shank

- Reduce weight of foot plate

- Select different motors (or gear up current motors) to increase adjustment speed