Butterfly Rolling Manipulation

Overview

Team Members

Eric Bell (Mechanical Engineer, 2010)

William Fan (Mechanical Engineer, 2011)

Ben Kolodner (Mechanical Engineer, 2010)

Mechanical Design

Parts List

The Hand:Butterfly Shape

The Mount

The Roller

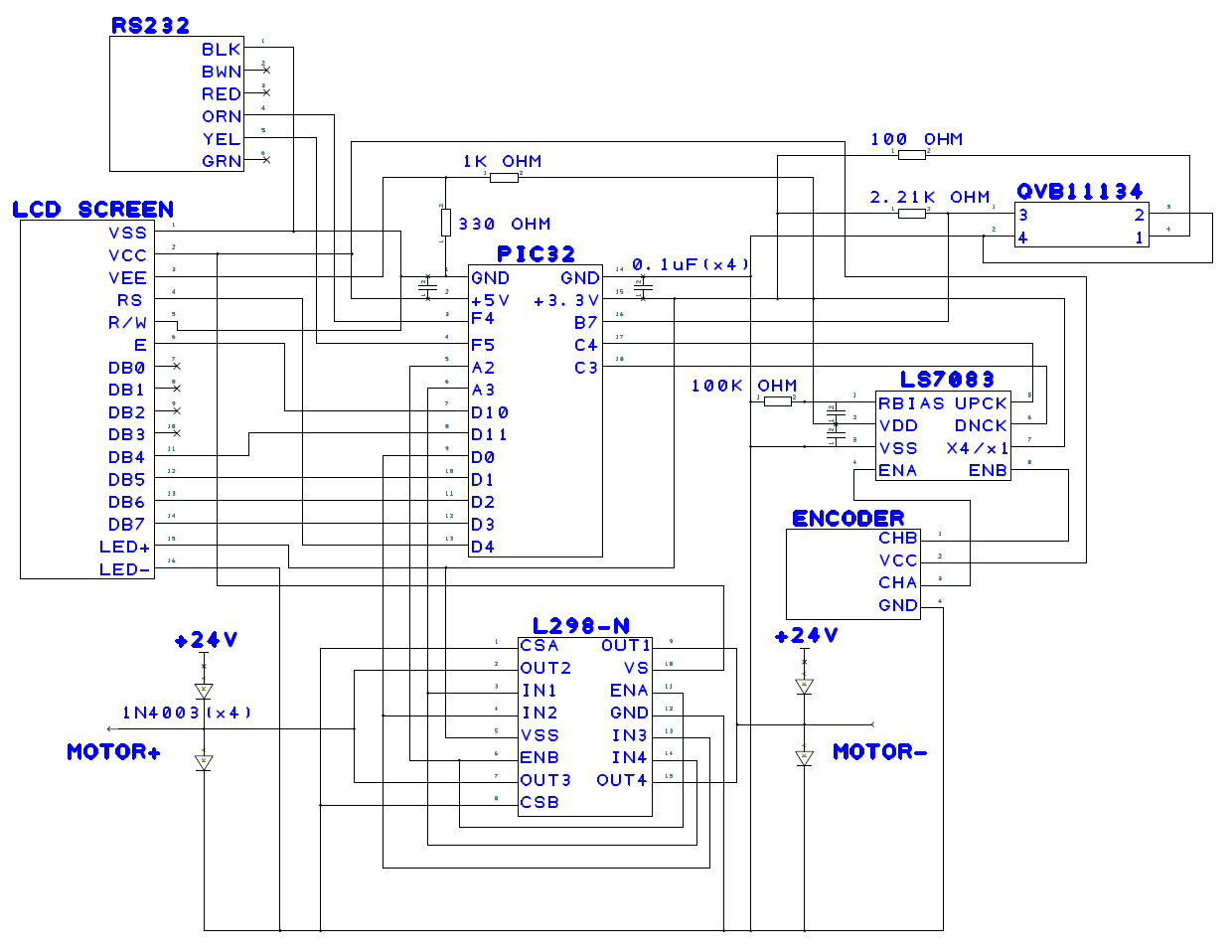

Circuit

Parts List

- PIC32 NU32 Board + PIC USB cable

- RS232 cable

- HD44780 LCD

- 5k potentiometer (1)

- 100 ohm resistor (3)

- 2.2 kohm resistor (1)

- 3.3 kohm resistor (1)

- 0.1uF capacitor (5)

- L298N H-bridge

- 14N002 diodes (4)

- LS7083 decoder

- Pittman GM8724S017 24V motor

- Protoboard/breadboard

Circuit Diagram

Motor

A Pittman GM8724S017 24V motor was chosen for the apparatus. Information for the motor can be found [here]. Originally, our motor did not use a gear-head in order to reduce backlash. However, this continuously burned out our H-Bridges, so a motor with a 19.5:1 gear-head ratio was selected to provide additional torque.

H-bridge disclaimer

Code

Processing

The purpose of the processing code is to plot the actual movement of the motor against the reference trajectory. The code produces a reference trajectory based on the given equation, a constant time interval, and a k-value and produces 2000 reference points for the motor to follow. Because processing plots one data point per pixel, only every other reference point is saved into an array in the pic. At every reference point, the encoder reads the position and also records this actual position at every other reference point into a separate array. These arrays are fed from the pic into a computer using an RS232 cable when the “read data” button is pushed in the processing GUI. Processing then plots these arrays.

Processing is also used to reset the hand. By pushing the reset button in the processing GUI, processing activates an interrupt which tells the hand to reset using the light sensor and run the main code again.

<insert graph>

Based on the graphs created in processing, the PD control was very effective in controlling the motor. Minor offsets occurred consistently at the beginning and end of each run due to backlash from the motor, but the actual position was very close to the reference trajectory a majority of the time.

Results

Next Steps

- Eliminate backlash via gearless motor

- Sense position of the disc using copper tape and resistive wire

- Implement PID control on motor position, along with control of PID using sensing of disc

- Test other butterfly shapes with lower or higher curvature

- Test other disc shapes with different center of masses and weights

- Replace H-Bridges with nicer ones that can take higher amperage