Brushless DC Motors

Overview

Brushless DC (BLDC) motors are similar to Brushed DC Motors, except the commutation is done electronically, and the permanent magnets are on the rotor and the coils on the stator. Instead of using the brushes and the rotation of the commutator to power the coils, external circuitry is used. Brushless DC motors are generally more expensive and the extra effort to construct the circuitry must be considered. However, BLDCs can be more efficient under light loads, typically have better power-to-weight ratios and produce less wear on internal components. BLDCs are used in computer hard drives, CD/DVD players, and PC cooling fans and electric cars.

Commutation Circuitry

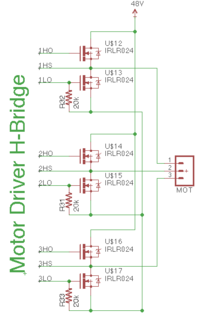

Unlike a DC motor, which is automatically commutated by the rotation of its brushes, a brushless DC motor can only be commutated by changing the voltage level on each of its three inputs. During each phase of the commutation one input of the BLDC motor will be at the voltage supply level, one will be floating and one will be at ground. This can be accomplished using an H-bridge configuration.

Because the controller must change the voltage levels on the motor inputs, the controller needs a way of determining the motor's rotational position. A typical motor will include a Hall Effect sensor encoder or some other type of rotary encoder. More advanced drive systems will use the back EMF in the coils to determine the rotor position.

Commutation Pattern

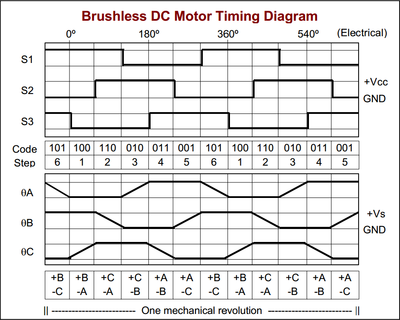

For a motor with a hall effect sensor encoder a typical commutation diagram is shown in the image to the right. The commutation diagram was taken from the Pittman Motor 4443S013 Datasheet. Sample code for the dsPIC33 based on this commutation pattern is shown below.

References

- Wikipedia, "Brushless DC electric motor", http://en.wikipedia.org/wiki/Brushless_motors