Difference between revisions of "LIMS Air Hockey Table"

| Line 1: | Line 1: | ||

==Overview== |

==Overview== |

||

The LIMS air hockey table can be used for applications with low-friction environments. |

The LIMS air hockey table can be used for applications with low-friction environments. |

||

In the data shown below, the air hockey table was used to float a 6 and 8 inch clear acrylic disc. A portion of the holes on the surface of the air table were covered to increase pressure and flow. |

|||

==Air Hockey Table Specifications== |

==Air Hockey Table Specifications== |

||

Latest revision as of 10:32, 5 January 2009

Overview

The LIMS air hockey table can be used for applications with low-friction environments.

In the data shown below, the air hockey table was used to float a 6 and 8 inch clear acrylic disc. A portion of the holes on the surface of the air table were covered to increase pressure and flow.

Air Hockey Table Specifications

Manufacturer: KT Sports

Dimensions: 79” long 39” wide (inner table dimensions)

Hole spacing: 1” square intervals

Number holes: 79 x 39 total holes on table (before modification)

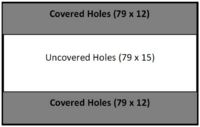

Modifications: covered 2x12 columns (12x79) on each side of table with clear packing table directly applied

to surface of table. Left uncovered 79 holes x 15 holes down center of table (long-ways)

Blower (Shop-Vac) Specifications

Manufacturer: Shop-Vac Corporation

Name: Ultra PRO

Model Number: 92L500A

12 Gallon 5.0 Hp

2” inner diameter flexible hose

Hose attached in blower mode, taped and held in place underneath table at plenum.

Pressure Measurements

Experimental Setup

1/4” hole drilled into bottom of plenum, 6” to the side of main blower intake

1/4” clear plastic hose inserted via press-fit into plenum (3/16” inner diameter)

Shop vac hose taped and held in place over plenum intake

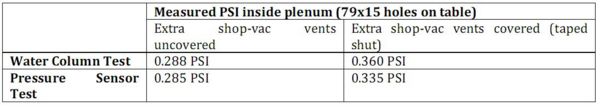

In blower mode, our shop vac appears to be leaking extra air out through various extra vents. To test the impact of the extra leakage, we performed one test with the shop vac in standard blower operation, and a second test with the extra venting holes covered with tape.

Test 1: Water Column

Vertically displaced 5” of water in a 3/16” inner diameter flexible clear hose (10 ft long)

1 inch water = 0.036 PSI

With Shop-vac vents unblocked: 4 inches water displaced * 2 * (0.036 PSI/inch) = 0.288 PSI in plenum

With Shop-vac vents blocked (taped): 5 inches water displaced * 2 * (0.036 PSI/inch) = 0.36PSI in plenum

Test 2: Analog Differential Pressure Sensor

Model Number: ASCX01DN

Sensitivity: 4.5 Volts / PSI

One input to pressure sensor connected to 3/16” inner diameter clear plastic hose (6” long, with other end in plenum)

Second input to pressure sensor open to room atmosphere

With blower off: Measured Offset Voltage of Sensor = 0.293 Volts

Blower on, Shop-vac vents unblocked: 1.29 Volts / (4.5 Volts/PSI) = 0.285 PSI

Blower on, Shop-vac vents blocked (taped): 1.51 Volts / (4.5 Volts/PSI) = 0.33 PSI

Tabulated Results

Flotation Capability

Experimental Setup

From the results of the pressure test, we covered the extra vents on the shop vac. This results in a higher pressure in the plenum and should increase the amount of weight we can support.

Shop-vac connected in blower mode with extra vents taped over.

Shop-vac taped and held in place at plenum.

Results

We tested 2 different sized clear polycarbonate circular discs (6” diameter, 8” diameter).

6" disc can support ~1.5lbs before it begins to drag

8" disc can support ~4.85lbs before it begins to drag