Difference between revisions of "Fans As Actuators"

| Line 3: | Line 3: | ||

==Types of Fans== |

==Types of Fans== |

||

===Axial (Propellor)=== |

===Axial (Propellor)=== |

||

| ⚫ | |||

This type of fan uses a fixed blade that produces airflow parallel to the direction of rotation. This fan design can be seen in many cooling applications, as it is designed to maximize the volume of air moved. |

This type of fan uses a fixed blade that produces airflow parallel to the direction of rotation. This fan design can be seen in many cooling applications, as it is designed to maximize the volume of air moved. |

||

| ⚫ | |||

===Centrifugal (radial)=== |

===Centrifugal (radial)=== |

||

| ⚫ | |||

A centrifugal fan is constructed with an impeller inside of a rigid housing and resembles a paddle wheel. Airflow is input through the center of the impellor and is output at a single radial vent. This type of fan is designed to increase the air pressure at its output, and is used in many blowing and inflating applications |

A centrifugal fan is constructed with an impeller inside of a rigid housing and resembles a paddle wheel. Airflow is input through the center of the impellor and is output at a single radial vent. This type of fan is designed to increase the air pressure at its output, and is used in many blowing and inflating applications |

||

| ⚫ | |||

==Driving and Controlling== |

==Driving and Controlling== |

||

Revision as of 20:43, 19 December 2008

Introduction

Types of Fans

Axial (Propellor)

This type of fan uses a fixed blade that produces airflow parallel to the direction of rotation. This fan design can be seen in many cooling applications, as it is designed to maximize the volume of air moved.

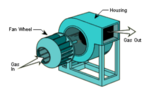

Centrifugal (radial)

A centrifugal fan is constructed with an impeller inside of a rigid housing and resembles a paddle wheel. Airflow is input through the center of the impellor and is output at a single radial vent. This type of fan is designed to increase the air pressure at its output, and is used in many blowing and inflating applications

Driving and Controlling

Important Practical Considerations

Directionality

Most prepackaged fans are optimized to spin in a single direction. In particular, both the physical shape and orientation of the blades as well as the controller for the electric motor are designed to allow for unidirectional operation. Even if the controller may be hacked to allow for bidirectional motion, the thrust will most likely be asymmetric.

To attain true bidirectional motion, one will typically have to select a bidirectional motor and propeller blade separately (avoid prepackaged fans). R/C airplane and helicopter hobby sites typically offer good starting points for such applications.

Phase Lag

One of the most significant practical limitations of using a fan as an actuator is the lag when accelerating the fan. Accelerating from one velocity to another velocity (increasing/decreasing thrust) physically takes time. The amount of time is typically proportional to the difference in velocities and can be on the order of seconds.

This phase lag limitation is due to the inherent design of many prepackaged fans as they are built to provide a constant velocity with no acceleration. (They are hence actuated by a motor with a small torque) This represents a typically blowing/venting application.

The phase lag of a fan is an important consideration for applications using fans to control their motion as this will increase the complexity of the controller.