Difference between revisions of "PCB Artist"

| Line 25: | Line 25: | ||

<br clear=all> |

<br clear=all> |

||

== |

==Creating the Board== |

||

Ordering Options: |

|||

*Barebones: These boards are very basic. They do not have solder mask (the green coating), or text on the board and the traces are exposed. However, they are fairly cheap (charged by area) and they ship in 1 business day. Perfect for prototyping. [http://www.barebonespcb.com More info] |

|||

===Getting Started=== |

|||

*33- Each 2 layer PCBs can be ordered for $33 each, shipping in about a week. These are complete, boards with screen printing and solder mask. The max size is 60 square inches. With the promo “student” the min qty of 4 is waived, allowing you to order a single board. [http://www.4pcb.com/index.php?load=content&page_id=130 More info] |

|||

To start a new PCB design follow these steps: |

|||

*Other promotions: Advanced Circuits offers various other promotions for students and first time customers. If you have questions, contact Jackie Sartin, our rep. [http://www.4pcb.com/index.php?load=content&page_id=129 More info] |

|||

1) File -> New, then select "New PCB Design" |

|||

2) The Wizard will open, selections in the wizard |

|||

*Specify size: (mil = 1/1000 of an inch) Note: The size of the board can be changed later, this is just to get started. |

|||

*Design Requirement: For most projects you will want a "Basic" 2-layer standard. More complex boards are significantly more expensive. |

|||

*Layers: If you have selected 2-layer standard, there are few options on this page, if you have more layers you can select power and ground planes. |

|||

*Board parameters: The default selection is fine for most projects |

|||

*The next few pages are about production- click next, this will be set up later. (Ignore all cost estimates- these drastically change later) |

|||

*Name your file and save it |

|||

You should have a board outline on your screen. You can select which layers you view using the interaction bar on the left. (If it isn't open go file>interaction bar, or press F9) |

|||

After ordering, it’s a good idea to call and make sure they have received your order, check the turn around date, promotions and any other info. |

|||

===Placing components=== |

|||

== Robot Snake Motion == |

|||

PCB Artist has a large libary of componets. From the screen with your board outline to add components you can do many things: |

|||

[[image:Serpentine_curves.jpg|thumb|300pix|right|Serpentine Curves]] |

|||

*Click the icon with the DIP in the top left of the scree |

|||

*Press F8 |

|||

*Add> Component |

|||

*Click "Add Component" at the bottom of the interaction bar |

|||

====Selecting your component==== |

|||

Real snake motion does not follow specified equations. However, research has proven that the serpentine motion of a snake can be modeled with the following equations (Saito etal, 72-73): |

|||

At this point it is important to know exactly what component you are using. |

|||

Open the "Add Component" window and make sure that the "Preview" box is checked. As you scroll through the component list, a preview of the part will be displayed. This also allows you to scroll quickly looking for the appropriate part. |

|||

Note: For many parts there are multiple package options, you can select this from the package drop down menu. |

|||

*If you are using an IC it is a good idea to see if they have the exact chip. You can do this by clicking find in the "add component" window and entering the part number. This search is very hard to use. If you know the manufacturer, select it under the libraries tab and scroll to see if your component is there. |

|||

*If you are using a basic SIP or DIP package find the "PCB" library, this has many selections for SIP and DIP components. Check the package type. An N, ie DIPN, indicates narrow packaging (300mil size, vs 600mil size) |

|||

*For other components, check to see if there is a designated library, ie "diode" |

|||

*If you are using a discrete component (resistor, capacitor etc) click the Discrete library, then look through the list. |

|||

Once you have found your component click "Add." The window will close and you can now place the part by clicking. To rotate the part, just press R. To flip the part (mirror image, for the back of the PCB) press F. (When you are done with the component you can either right click or press escape.) |

|||

<math>x(s)= \int_{0}^{s} \cos (\zeta_\sigma) d\sigma</math> |

|||

Once you have placed the component, measure it!!! Click the ruler icon on the lower left then click parts of the component to measure the distance between centers etc. Double check this with your part! |

|||

<math>y(s)= \int_{0}^{s} \sin (\zeta_\sigma) d\sigma </math> |

|||

====If you need to make a component==== |

|||

<math>\zeta_\sigma= a \cos (b\sigma) +c\sigma </math> |

|||

If you cannot find the necessary component you can build your own component. There are a couple of ways to do this: |

|||

*Add pads (add pad icon on the left - looks like a yellow doughnut) and then add outlines (the add shape icons on the middle left) |

|||

*Click libraries (Blue book on the top bar) and then create your own part using the wizard. If you do this, please add directions here. |

|||

=== General Building Notes=== |

|||

where the parameters ''a'', ''b'', and ''c'' determine the shape of the serpentine motion. The graph shows how the parameters influence the serpentine curve. Basically, ''a'' changes the appearance of the curve, ''b'' changes the number of phases, and ''c'' changes the direction. |

|||

*Changing properties of the compnents, pads and connections: Right click and select properties |

|||

*To change many things at once: Click the Abc in the menu bar, top, this will open a chart with the current pads, components and sizes. To change something, click and change a value. |

|||

* Grouping functions have not been found, however you can drag select to select multiple items. |

|||

*Through the Abc button (Design Technology Window) it is possible to change many aspects of your board, check here first! |

|||

*Adding Text, this will show up on silkscreen: Click the T on the left, then enter and place the text as you would with a component |

|||

===Wiring and Routing the Circuit=== |

|||

Have your schematic out for reference. |

|||

PCB artist is helpful because it allows you to connect two points that need to be connected, with a straight line, no routing. |

|||

*Click "Add unrouted connection" button on the left (pencil with two dots) |

|||

The serpentine curve can be modeled with a snake like robot by changing the relative angles between the snake robot segments using the following formula with the number of segments (n): |

|||

*Click the first connection point, then the second. This will leave a yellow line connecting the two points. |

|||

*Connect your entire circuit this way, it should look like yellow web. |

|||

*Go to Tools> Optimize nets to make this neater and the connections more intelligent. |

|||

Routing the Circuit |

|||

Once all of your connections are made, click the route icon on the left (blue and red wires crossing) |

|||

For now stick with the default settings, you can alter these later if you need to. |

|||

Click "Route." Routing will begin and a report will be generated. |

|||

Routes that show up in blue are on the bottom of a 2-layer board, red is on the top. |

|||

To select an entire route, click on part of that route, then press H this will highlight the entire signal. |

|||

<math>\phi_i = \alpha sin(\omega t +(i-1)\beta ) + \gamma, \left ( i=1, ..., n-1 \right )</math> |

|||

To unroute nets: Tools> unroute nets > All nets (This will bring you back to the yellow web) |

|||

====Tips on Routing==== |

|||

where α , β , and γ are parameters used to characterize the serpentine curve and are dependent on ''a'', ''b'', and ''c'' as shown below: |

|||

If you have a dense circuit with many signals, routing may be difficult, tips to try. After trying any of these things, click optomize nets under tools. |

|||

*Are your components efficiently placed? Would rotating something make it more efficient. |

|||

*When you click the route button, in the route options window increase the effort and passes. This also increases the time it takes to route something. |

|||

*Look at the desnset areas of the board (ie the center) can you move components, or rotate to free up some board space? |

|||

*Can you use a larger board. |

|||

*If you have assigned some routes to Power or Ground these are thicker by default. Unless you have a high power application, these can usually be standardized, see the Abc button. |

|||

*You can route nets by hand, much more complicated, and usually the computer is smarter, especially on complex designs. |

|||

===Design Check=== |

|||

<math>\alpha = a \left | \sin \left ( \frac{\beta}{2} \right ) \right | </math> |

|||

Once your board is routed, and before you order it, do a design check. |

|||

Click the design rule check on the bottom left (2 red bars) |

|||

Leave the default for basic designs. A design rule check report will be generated. If you have errors, ie pads are too small, correct them either manually by right clicking and editing or by using the Abc button at the top to change many things at once. |

|||

== Ordering == |

|||

<math>\beta = \frac{b}{n} </math> |

|||

Once you have a fully routed design which is error free, and has been double checked you are ready to order your board. |

|||

From PCB artist you can order most options, except bare bones. To do this click order now at the very top and follow the directions. For support, call Advanced Cirucits (number at the top of the screen) or there is an ordering tutorial avalible from [http://www.4pbc.com their website]. |

|||

===Ordering Options=== |

|||

<math>\gamma = -\frac{c}{n} </math> |

|||

*Barebones: These boards are very basic. They do not have solder mask (the green coating), or text on the board and the traces are exposed. However, they are fairly cheap (charged by area) and they ship in 1 business day. Perfect for prototyping. [http://www.barebonespcb.com More info] |

|||

*33- Each 2 layer PCBs can be ordered for $33 each, shipping in about a week. These are complete, boards with screen printing and solder mask. The max size is 60 square inches. With the promo “student” the min qty of 4 is waived, allowing you to order a single board. [http://www.4pcb.com/index.php?load=content&page_id=130 More info] |

|||

*Other promotions: Advanced Circuits offers various other promotions for students and first time customers. If you have questions, contact Jackie Sartin, our rep. [http://www.4pcb.com/index.php?load=content&page_id=129 More info] |

|||

The equations above for φ<sub>i</sub>,α,β, and γ were used in this snake like robot as shown in the [[Robot Snake#PIC Code|code section]]. |

|||

After ordering, it’s a good idea to call and make sure they have received your order, check the turn around date, promotions and any other info. |

|||

<br clear=all> |

|||

== Mechanical Design == |

|||

[[image:FullSnake.jpg|thumb|right|The Snake]] |

|||

The robotic snake consists of a head segment and several body segments. The head segment houses the onboard microcontroller and xBee radio. The body segments house the servo motors and the batteries required to power each motor. As the snake is designed to be modular, there is no limit to the number of body segments. More segments will allow it to move more smoothly, while fewer segments will be easier to control. For this design, seven body segments were used due to material limitations. |

|||

Mechanically, the snake is designed to move in a serpentine motion, imitating the motion of a real snake. As discussed above, real snakes move with anisotropic coefficients of friction. It is difficult to locate materials with this property, but passive wheels satisfy the friction requirements. The friction will be lower in the direction of rolling, thus providing the required difference in friction. The only problem with this approach is that the wheel may slide in the normal direction if the weight applied to the wheel is not sufficient. |

|||

===Parts List=== |

|||

*Motors: Futaba S3004 standard ball bearing RC servo motor, Tower Hobbies LXZV41 $12.99 |

|||

*Wheels: McMasterCarr Acetal Pulley for Fibrous Rope for 1/4" Rope Diameter, 3/4" OD McMasterCarr 8901T11 $1.66 |

|||

*O-Rings (Tires): McMasterCarr Silicone O-Ring AS568A Dash Number 207, Packs of 50 McMasterCarr 9396K209 $7.60/50 |

|||

*PVC Pipe: McMasterCarr Sewer & Drain Thin-Wall PVC Pipe Non-Perforated, 3" X 4-1/2' L, Light Green McMasterCarr 2426K24 $7.06 |

|||

*1/8th inch plastic for chassis: (Shop Stock) or McMasterCarr Polycarbonate Sheet 1/8" Thick, 12" X 12", Clear, McMasterCarr, 8574K26 $6.32 |

|||

*Dowel Pins: 1" long, 1/4" diameter |

|||

*Sheet Metal: For the connecting segments |

|||

*Fasteners: Screws for the servos and chassis, washers for the standoffs |

|||

*Standoffs: Used 1" and 1/2" to achieve a level snake |

|||

*Velcro: To attach battery packs and housing to the chasis |

|||

*Ball caster: For the head |

|||

=== The Body Segments === |

|||

[[image:Chasis.jpg|thumb|right|A Single Chasis Without a Servo]] |

|||

Each of the body segments are identical and includes a chassis, a servo, a connector, standoffs and two passive wheels as can be seen in the picture. |

|||

[http://www.youtube.com/watch?v=wBcJkNHEaAs Video of 3 body segments moving] |

|||

==== Chassis ==== |

|||

The base of the chassis is made from a thin (approx. 1/8th inch) piece of polycarbonate. The chassis must be wide enough to hold a servo motor with a AAA battery pack on each side and long enough for the servo and a standoff (the connection for the previous segment). The polycarbonate was cut into a rectangle to meet the specifications for our servo motor. Five holes were then drilled in the rectangle, four to mount the servo and one for the standoff. The holes are drilled to allow the servo to be located in the center of the chassis. |

|||

==== Connector ==== |

|||

A connector was machined to attach to the servo horn of one body segment and to attach to the next segment's standoff. The length of this connector is about 3 inches and is just long enough to prevent collision between segments. A shorter beam allows for greater torque. This connection needs to be as tight as possible and the beam must be mounted perpendicular to the chassis. |

|||

[[image:ChasisUnderside.jpg|thumb|right|The Underside of a Chassis]] |

|||

====Standoffs ==== |

|||

Standoffs were used to attach the servo to the chassis and to attach the connector to the chassis. Two standoffs (1 in and 1/2 in) and several washers were used to make the connector parallel to the ground. |

|||

==== Passive Wheels ==== |

|||

[[image:Wheel.jpg|thumb|left|A Passive Wheel on the Dowel Pin]] |

|||

Passive wheels were mounted to the bottom of the chassis. Each wheel was made of a 3/4 inch pulley and an o-ring. The o-ring was used to increase friction with the ground. The wheels have been set on polished metal dowel pins which allow the wheels to rotate more freely than when placed on wooden dowels. The dowel pin axles were mounted (hot glue works but is not very strong) in the center of the segment. The center of the segment is not the center of the polycarbonate rectangle. Instead, the entire segment length is the distance from the standoff on one chassis to the center of the servo horn on the other. In this project, the length of the connector was made to be about half the length of the segment. Therefore, the wheels were placed at the same location as the stand off as can be seen in the image. The wheels are held in place with zip ties. |

|||

<br clear=all> |

|||

==== Fully Assembled Body Segment ==== |

|||

[[image:BuiltChasis.jpg|thumb|right|A Chassis Built Showing a Standoff and Batteries]] |

|||

[[image:BuiltChasis2_MLS.jpg|thumb|right|Chassis with Batteries Removed]] |

|||

A fully assembled chassis has a mounted servo and is connected to a segment on either side. AAA batteries packs were attached to the sides of the motor with velcro to allow easy removal. The small electronic circuit board for each segment was mounted on the front of the motor to allow easy access to the switch. (See Electronic Design for more information on the circuit board and batteries) |

|||

<br clear=all> |

|||

Revision as of 16:44, 13 December 2008

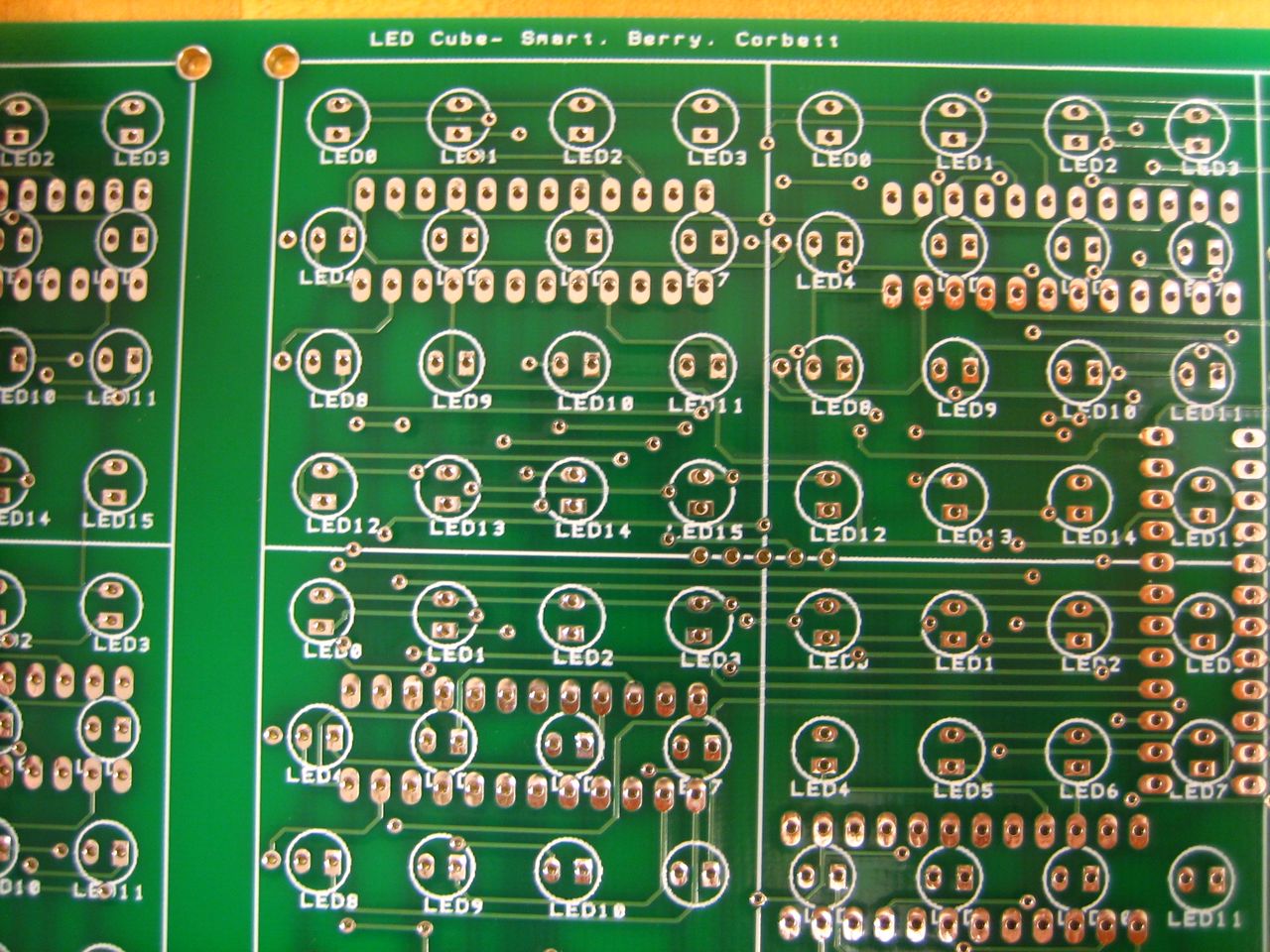

Advanced Circuits and PCB Artist

Advanced Circuits (www.4pcb.com) is a company based in Colorado known for their quick turn around and good prices on low volume printed circuit board (PCB) orders. This has been the main supplier for PCBs created by students for class or research at Northwestern.

Previously, the PCB was created in TraxxMaker or other CAD PCB program, many of which are outdated and difficult to use. Advanced Circuits has created PCB Artist, free software to create schematics and PCBs. This software is designed to order only from Advanced Circuits, although the file type produced is .brd. This somewhat simplistic software is very intuitive (once comfortable) and allows for simple changes and editing. Additionally, the component library offered is up to date and contains many specific components. This Wiki page will cover the development and ordering process of the a simple PCB board.

Contact at Advanced Circuits

Jackie Sartin - Regional Sales Manager

E-mail: jackies@4pcb.com Call: 1-800-979-4PCB (4722) Ext: 1685

Getting Setup

- Have a complete circuit schematic and know exactly what parts (including part numbers) you are using.

- Download the software Or, type “PCB Artist” into google. Then click the download button in the middle of the screen.

Creating the Board

Getting Started

To start a new PCB design follow these steps: 1) File -> New, then select "New PCB Design" 2) The Wizard will open, selections in the wizard

- Specify size: (mil = 1/1000 of an inch) Note: The size of the board can be changed later, this is just to get started.

- Design Requirement: For most projects you will want a "Basic" 2-layer standard. More complex boards are significantly more expensive.

- Layers: If you have selected 2-layer standard, there are few options on this page, if you have more layers you can select power and ground planes.

- Board parameters: The default selection is fine for most projects

- The next few pages are about production- click next, this will be set up later. (Ignore all cost estimates- these drastically change later)

- Name your file and save it

You should have a board outline on your screen. You can select which layers you view using the interaction bar on the left. (If it isn't open go file>interaction bar, or press F9)

Placing components

PCB Artist has a large libary of componets. From the screen with your board outline to add components you can do many things:

- Click the icon with the DIP in the top left of the scree

- Press F8

- Add> Component

- Click "Add Component" at the bottom of the interaction bar

Selecting your component

At this point it is important to know exactly what component you are using. Open the "Add Component" window and make sure that the "Preview" box is checked. As you scroll through the component list, a preview of the part will be displayed. This also allows you to scroll quickly looking for the appropriate part. Note: For many parts there are multiple package options, you can select this from the package drop down menu.

- If you are using an IC it is a good idea to see if they have the exact chip. You can do this by clicking find in the "add component" window and entering the part number. This search is very hard to use. If you know the manufacturer, select it under the libraries tab and scroll to see if your component is there.

- If you are using a basic SIP or DIP package find the "PCB" library, this has many selections for SIP and DIP components. Check the package type. An N, ie DIPN, indicates narrow packaging (300mil size, vs 600mil size)

- For other components, check to see if there is a designated library, ie "diode"

- If you are using a discrete component (resistor, capacitor etc) click the Discrete library, then look through the list.

Once you have found your component click "Add." The window will close and you can now place the part by clicking. To rotate the part, just press R. To flip the part (mirror image, for the back of the PCB) press F. (When you are done with the component you can either right click or press escape.)

Once you have placed the component, measure it!!! Click the ruler icon on the lower left then click parts of the component to measure the distance between centers etc. Double check this with your part!

If you need to make a component

If you cannot find the necessary component you can build your own component. There are a couple of ways to do this:

- Add pads (add pad icon on the left - looks like a yellow doughnut) and then add outlines (the add shape icons on the middle left)

- Click libraries (Blue book on the top bar) and then create your own part using the wizard. If you do this, please add directions here.

General Building Notes

- Changing properties of the compnents, pads and connections: Right click and select properties

- To change many things at once: Click the Abc in the menu bar, top, this will open a chart with the current pads, components and sizes. To change something, click and change a value.

- Grouping functions have not been found, however you can drag select to select multiple items.

- Through the Abc button (Design Technology Window) it is possible to change many aspects of your board, check here first!

- Adding Text, this will show up on silkscreen: Click the T on the left, then enter and place the text as you would with a component

Wiring and Routing the Circuit

Have your schematic out for reference. PCB artist is helpful because it allows you to connect two points that need to be connected, with a straight line, no routing.

- Click "Add unrouted connection" button on the left (pencil with two dots)

- Click the first connection point, then the second. This will leave a yellow line connecting the two points.

- Connect your entire circuit this way, it should look like yellow web.

- Go to Tools> Optimize nets to make this neater and the connections more intelligent.

Routing the Circuit Once all of your connections are made, click the route icon on the left (blue and red wires crossing) For now stick with the default settings, you can alter these later if you need to. Click "Route." Routing will begin and a report will be generated. Routes that show up in blue are on the bottom of a 2-layer board, red is on the top.

To select an entire route, click on part of that route, then press H this will highlight the entire signal. To unroute nets: Tools> unroute nets > All nets (This will bring you back to the yellow web)

Tips on Routing

If you have a dense circuit with many signals, routing may be difficult, tips to try. After trying any of these things, click optomize nets under tools.

- Are your components efficiently placed? Would rotating something make it more efficient.

- When you click the route button, in the route options window increase the effort and passes. This also increases the time it takes to route something.

- Look at the desnset areas of the board (ie the center) can you move components, or rotate to free up some board space?

- Can you use a larger board.

- If you have assigned some routes to Power or Ground these are thicker by default. Unless you have a high power application, these can usually be standardized, see the Abc button.

- You can route nets by hand, much more complicated, and usually the computer is smarter, especially on complex designs.

Design Check

Once your board is routed, and before you order it, do a design check. Click the design rule check on the bottom left (2 red bars) Leave the default for basic designs. A design rule check report will be generated. If you have errors, ie pads are too small, correct them either manually by right clicking and editing or by using the Abc button at the top to change many things at once.

Ordering

Once you have a fully routed design which is error free, and has been double checked you are ready to order your board. From PCB artist you can order most options, except bare bones. To do this click order now at the very top and follow the directions. For support, call Advanced Cirucits (number at the top of the screen) or there is an ordering tutorial avalible from their website.

Ordering Options

- Barebones: These boards are very basic. They do not have solder mask (the green coating), or text on the board and the traces are exposed. However, they are fairly cheap (charged by area) and they ship in 1 business day. Perfect for prototyping. More info

- 33- Each 2 layer PCBs can be ordered for $33 each, shipping in about a week. These are complete, boards with screen printing and solder mask. The max size is 60 square inches. With the promo “student” the min qty of 4 is waived, allowing you to order a single board. More info

- Other promotions: Advanced Circuits offers various other promotions for students and first time customers. If you have questions, contact Jackie Sartin, our rep. More info

After ordering, it’s a good idea to call and make sure they have received your order, check the turn around date, promotions and any other info.