Difference between revisions of "Northwestern Design Competition"

From Mech

Jump to navigationJump to searchNickMarchuk (talk | contribs) (→DC2012) |

NickMarchuk (talk | contribs) (→DC2012) |

||

| Line 2: | Line 2: | ||

'''Workshop 1, TBD''' |

'''Workshop 1, TBD''' |

||

How to program in MPLABX |

*How to program in MPLABX |

||

How to use the bootloader to put code on the NU32 |

*How to use the bootloader to put code on the NU32 |

||

Digital output I/O (read a button and flash an LED) |

*Digital output I/O (read a button and flash an LED) |

||

Analog input |

*Analog input |

||

PWM output |

*PWM output |

||

'''Milestone 1''' |

'''Milestone 1''' |

||

If a pushbutton is pressed, read the value of a potentiometer and change the brightness of an LED to the corresponding value with PWM |

*If a pushbutton is pressed, read the value of a potentiometer and change the brightness of an LED to the corresponding value with PWM |

||

'''Workshop 2, TBD''' |

'''Workshop 2, TBD''' |

||

Optical isolation for motors and RC servos |

*Optical isolation for motors and RC servos |

||

Powering a motor with an h-bridge |

*Powering a motor with an h-bridge |

||

Writing to the 16x2 character LCD |

*Writing to the 16x2 character LCD |

||

Laser detection of retroreflective tape / Optical line detection |

*Laser detection of retroreflective tape / Optical line detection |

||

2 1/2D design |

*2 1/2D design |

||

'''Milestone 2''' |

'''Milestone 2''' |

||

Optically isolate a motor |

*Optically isolate a motor |

||

Read a potentiometer and write its voltage to the LCD |

*Read a potentiometer and write its voltage to the LCD |

||

Control the motor velocity based on the potentiometer reading |

*Control the motor velocity based on the potentiometer reading |

||

Mount a phototransistor to a laser and detect a scoring zone OR detect a line of electrical tape on white paper |

*Mount a phototransistor to a laser and detect a scoring zone OR detect a line of electrical tape on white paper |

||

Workshop 3, TBD |

'''Workshop 3, TBD''' |

||

Line following |

*Line following |

||

Laser cutting |

*Laser cutting |

||

'''Workshop 4, TBD''' |

'''Workshop 4, TBD''' |

||

Line following and detecting the crate |

*Line following and detecting the crate |

||

'''Milestone 4''' |

'''Milestone 4''' |

||

Finish laser cutter training |

*Finish laser cutter training |

||

First draft of a robot chassis |

*First draft of a robot chassis |

||

One of the following: |

*One of the following: |

||

Follow a line |

**Follow a line |

||

Detect a crate or scoring zone and drive towards it |

**Detect a crate or scoring zone and drive towards it |

||

==DC2011== |

==DC2011== |

||

Revision as of 11:52, 20 December 2011

DC2012

Workshop 1, TBD

- How to program in MPLABX

- How to use the bootloader to put code on the NU32

- Digital output I/O (read a button and flash an LED)

- Analog input

- PWM output

Milestone 1

- If a pushbutton is pressed, read the value of a potentiometer and change the brightness of an LED to the corresponding value with PWM

Workshop 2, TBD

- Optical isolation for motors and RC servos

- Powering a motor with an h-bridge

- Writing to the 16x2 character LCD

- Laser detection of retroreflective tape / Optical line detection

- 2 1/2D design

Milestone 2

- Optically isolate a motor

- Read a potentiometer and write its voltage to the LCD

- Control the motor velocity based on the potentiometer reading

- Mount a phototransistor to a laser and detect a scoring zone OR detect a line of electrical tape on white paper

Workshop 3, TBD

- Line following

- Laser cutting

Workshop 4, TBD

- Line following and detecting the crate

Milestone 4

- Finish laser cutter training

- First draft of a robot chassis

- One of the following:

- Follow a line

- Detect a crate or scoring zone and drive towards it

DC2011

Milestone 1

- On a button press, read the value of a potentiometer and change the brightness of an LED accordingly using PWM. Note: Do not use an h-bridge or motor as previously assigned.

- Due before Workshop 2 on Wed, 2/9.

- Sample code from Workshop 1

Milestone 2

- Due before Workshop 3 on Wed, 2/23.

- Goals:

- Use code from NU32v2: Nokia 5110 LCD and NU32v2: Analog Input to read a potentiometer and print the voltage to the Nokia 5110

- Optically isolate a motor and control its velocity based on the potentiometer reading

- Do 1 of the following:

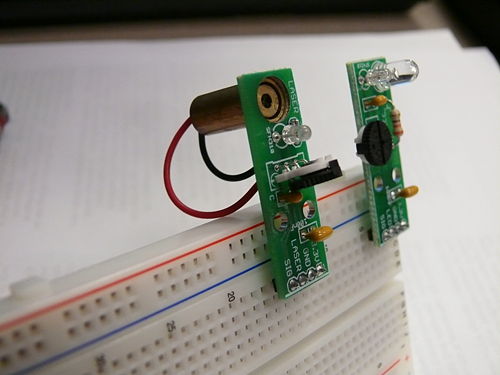

- Mount a phototransistor to a laser and detect a cake OR

- Detect a line of electrical tape on white paper with an optoreflector

- Datasheets

- HBridge_L293D.pdf - H-bridge for driving a DC motor

- Optocoupler_A847.pdf - Optocoupler to optically isolate your H-bridge

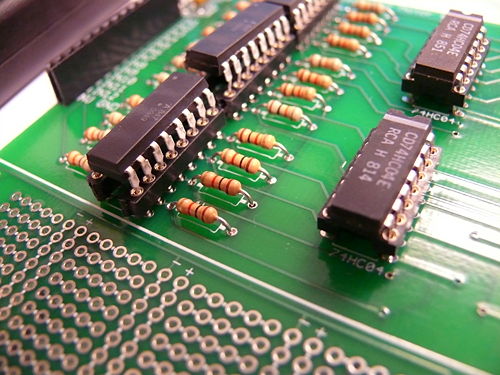

- HexInverter_74HC04.pdf - Inverting chip to digitize optocoupler output

- Optoreflector_OPB740.pdf - Optoreflector to detect lines or color

- Optoreflector_QRE1113.pdf - Optoreflector to detect lines or color

- Phototransistor_SFH310.pdf - Phototransistor to detect lines, color, or laser reflections

- Notes

- DC2011_WS2_OpticalIsolation.pdf - How to optically isolate an h-bridge and servo motor using the A847 and 74HC04

- DC2011_WS2_OpticalSensors.pdf - How to use the SFH310 to detect a cake and use the OPB740 or QRE1113 for line following

- DC2011_WS2_Code.zip - Example code for the NU32v2 that will:

- Control a DC motor hooked up to an optically isolated h-bridge, and control an optically isolated RC servo motor

- Respond to serial commands to control the motors, write to the Nokia 5110, and read two analog signals

Milestone 4

- Due before Wed, 3/16

- Finish laser training, at least one person per team

- Construct a prototype chassis for your robot

- Do one of the following:

- Follow part of the line on the 36" x 96" printout of this pdf

- Detect a cake somewhere on the floor and drive to it

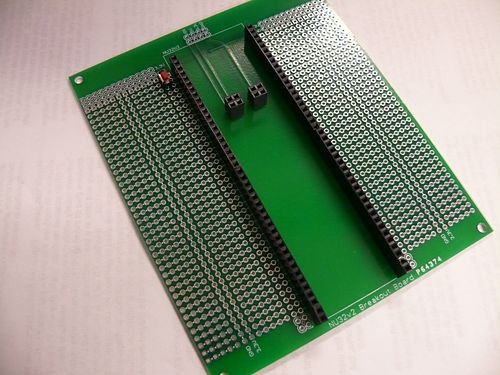

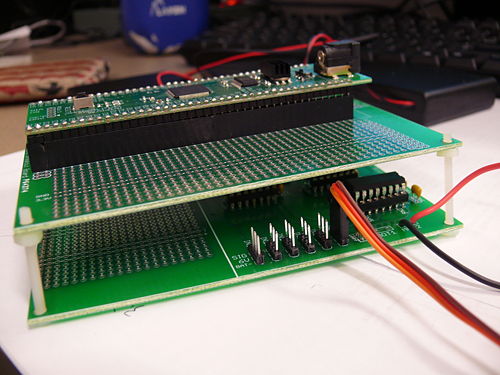

Breakout Boards

- Image of the breakout boards

- Circuit schematic of the breakout boards

- This board contains:

- A spot to plug in the NU32v2 with some prototyping area

- The optical isolation circuit with some prototyping area, the same size as the NU32v2 breakout board so it can be stacked on top

- 8 SFH310 with LED breakout boards

- 4 SFH310 with laser diode breakout boards

- 1 LIS352AX accelerometer breakout board

- 1 LSM303DHL tilt-compensated compass breakout board

- 1 LPY550AL gyroscope breakout board

- 1 LS7366R encoder decoder breakout board

- 1 TCS3103 color sensor breakout board

- How to use the boards:

Brochure for 2011

Previous Years

Wiki pages on sensors, actuators, programming, and microcontrollers: use pages below

- Parts in the DC2008 quick start pack

- PIC C intro slides, as presented 2008/01/24 (pdf)

- PIC interfacing slides, as presented 2008/01/28 (pdf)

- Link to all sample PIC code here.

Sensors and actuators for DC

- Solderless Breadboard & wiring that works

- Using LEDs & IREDs

- Using a laser

- Infrared reflectivity

- Using phototransistors

- Sensing optical tape

- Comparators : the analog digital interface

- Faulhaber MiniMotor SA gearmotor with encoder, as well as the local wiki page

- Adding a magnetic encoder to a GM3 Gearmotor

- Using magnetic switches (Hall Effect)

- Driving high-current devices: several options

- Driving a Stepper Motor

- Driving an RC Servo

- Accelerometers

- Strain gauges

- Basic Stamp Microcontroller Not recommended for DC2008

- NiMH rechargable batteries and chargers

Prof. Peshkin's favorite datasheets