Difference between revisions of "High Speed Motor Control"

DanielCornew (talk | contribs) |

DanielCornew (talk | contribs) |

||

| Line 37: | Line 37: | ||

There are two other component to the parallelogram assembly. One is a 22 inch by 1/2 inch length of carbon-nomex-carbon. This piece has one pin mounted 1 inch away from one end, and another pin mounted 10 inches away from that. The other piece is a 12 inch long piece of aluminum that has been bent into a 1 inch by in inch U-shape. This piece has two ball-bearing epoxied into it 10 inches apart. |

There are two other component to the parallelogram assembly. One is a 22 inch by 1/2 inch length of carbon-nomex-carbon. This piece has one pin mounted 1 inch away from one end, and another pin mounted 10 inches away from that. The other piece is a 12 inch long piece of aluminum that has been bent into a 1 inch by in inch U-shape. This piece has two ball-bearing epoxied into it 10 inches apart. |

||

The longer piece of carbon has the pin closest to its end press fit into the ball bearing mounted into the motor arm. The U-shaped piece of aluminum has on ball bearing slid onto the other motor arm, and secured with a snap ring. |

The longer piece of carbon has the pin closest to its end press fit into the ball bearing mounted into the motor arm. The U-shaped piece of aluminum has on ball bearing slid onto the other motor arm, and secured with a snap ring. The remaining ball bearing is then slid onto the reaming pin in the long piece of carbon and secured with a snap ring. |

||

The position of the motors relative to one another in then adjusted unit the arms move freely, and then fastened in place. |

|||

==Electrical Design== |

==Electrical Design== |

||

Revision as of 02:03, 16 March 2010

Overview

The project suggested was to design a system for high speed motor control using the PIC 32. To demonstrate the motor control, a two degree of freedom (2-DOF) parallelogram robot arm was designed to follow paths specified in a MATLAB gui.

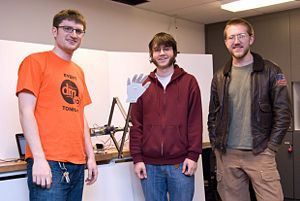

Team Members

- Sam Bobb (Electrical Engineering senior, left)

- Daniel Cornew (Mechanical Engineering junior, right)

- Ryan Deeter (Mechanical Engineering junior, middle)

Mechanical Design

Theory of Parallelogram Design

Equations of Motion

Commanding the arm is much easier for a user to do in x- and y- coordinates than in motor angles or encoder counts. Therefore, equations were required that would translate x- and y- coordinates into angles from horizontal and then into encoder counts. Equations to express the reverse (encoder counts to angles to x- and y- coordinates) were also needed to evaluate the accuracy of the execution with respect to the command path.

Note: is used to calculate in the MATLAB code and is not ever sent to the PIC.

Materials and Construction

The Motors are mounted into right-angle pieces of aluminum via screws in the face-plate of the motors. Each right angle has a slot milled into its base, and there is a flat aluminum base that also has a slot milled into it. The right angles are secured to this base with bolts, nuts, and lock washers. This slotted construction allows the position of the motors to be adjusted in order to ensure free movement of the arms.

Attached to each motor is a carbon fiber arm. These arms are 1/2 inch thick carbon-nomex-carbon layups. (Nomex is a material that provides rigidity to carbon fiber.) Each arm has an aluminum block with a hole and set screw for mounting epoxied to one end. One of these carbon fiber arms has a bearing mounted in it 10 inches away from the motor shaft, and the other has a pin mounted at the same distance.

There are two other component to the parallelogram assembly. One is a 22 inch by 1/2 inch length of carbon-nomex-carbon. This piece has one pin mounted 1 inch away from one end, and another pin mounted 10 inches away from that. The other piece is a 12 inch long piece of aluminum that has been bent into a 1 inch by in inch U-shape. This piece has two ball-bearing epoxied into it 10 inches apart.

The longer piece of carbon has the pin closest to its end press fit into the ball bearing mounted into the motor arm. The U-shaped piece of aluminum has on ball bearing slid onto the other motor arm, and secured with a snap ring. The remaining ball bearing is then slid onto the reaming pin in the long piece of carbon and secured with a snap ring.

The position of the motors relative to one another in then adjusted unit the arms move freely, and then fastened in place.

Electrical Design

Overview

Components

Circuit Diagram

GUI

The GUI was programmed in MATLAB using the "guide" function. The GUI code calls the other MATLAB functions and is rather small as far as the amount of new code in contains.

[insert screenshot of gui]

Usage

The GUI is made up of four main sections that allow a user to control the path and motor control parameters of the arm and plot the results.

The first section is the "Path" section, which allows users to specify the type of path the arm will follow. There are currently three path choices: "go to," "circle," and "trace." The "go to" path allows the user to specify a point that the arm will go to from its current position in five seconds. The "circle" path is determined through five values. The first two are the (x, y) of the center of the circle. The next two are coefficients on sin and cosine terms that are effectively the radii [CHECK THIS WITH SAM}. The last value is the time in seconds for the arm to complete the circle. In the final path, "trace," users input four (x, y) positions and the arm moves from the first to the fourth and back to the first with two seconds in between points. The GUI could easily be changed so that the user specifies (x, y, t) and controls the time between points, but this would require velocity-based failure checking in the code to ensure that the user did not give a command that was dangerous to the arm.

The section just to the right of the "Path" section allows for further manipulation of the path and motor control. A checkbox controls whether or not the specified path loops (note: "go to" cannot loop). Beneath the checkbox is a section labeled "PID Control" and it lets users adjust the coefficients kp (proportional), ki (integral) and kd (derivative) on the fly by pressing the "Update" button.

The section on the far right is used to communicate between MATLAB and the PIC. A COM port is specified for communication. The "Connect" button opens the COM port, and the "Disconnect" button closes it. The "Start" button runs whichever path is specified in the "Path" section, and "Pause" pauses the path (note: to unpause, click the "Start" button again while paused).

The final section of the GUI is the "Graphs" section. This section plots the path of the arm in either "theta vs t" or "x vs y," as selected by the radio buttons. Plotted in COLOR is the path that the PIC tried to execute, and the COLOR plot shows the actual path of the arm, for comparison. INCLUDE SOMETHING ABOUT THE GET DATA AND CONTINUOUS LOG BUTTONS!

Code

Using MATLAB's "guide" function when creating GUIs makes for rather straightforward coding. When a component is added to the GUI (be it a button, text field, etc.), MATLAB adds a block of code to an automatically generated m-file. These blocks are functions, which means that programming them requires the use of handles. Here is an example:

function xCoor_Callback(hObject, eventdata, handles)

% hObject handle to xCoor (see GCBO)

% eventdata reserved - to be defined in a future version of MATLAB

% handles structure with handles and user data (see GUIDATA)

if get(handles.goToButton, 'Value') == 1

xCoor = get(hObject, 'String');

end

This block of code is for the x-coordinate of the "Go To" path option. The if statement utilizes handles so that the "Go To" button's function can be accessed from the x-coordinate function. This block sets the x-coordinate of the "Go To" command to the user specified value in the GUI if the "Go To" button is selected.

Code

Overview

PIC C Code

MATLAB Code

Results

It was awesome.

Next Steps

Acknowledgements

We would like to acknowledge Professor Lynch, Nick Marchuk and Andy Long for their instruction and guidance throughout this project.