Difference between revisions of "PIC Servo Controller"

From Mech

Jump to navigationJump to searchm (→Circuit) |

|||

| Line 1: | Line 1: | ||

==Code== |

|||

<pre> |

|||

#include <18f4520.h> |

|||

#device ADC=10 // set ADC to 10 bit accuracy |

|||

#fuses HS,NOLVP,NOWDT,NOPROTECT |

|||

#use delay(clock=40000000) |

|||

#use rs232(baud=19200, UART1) // hardware uart much better; uses RC6/TX and RC7/RX |

|||

#define PanTorqueMax 650 // 650 corresponds to 100% duty cycle for driving the motor full on in one dirction |

|||

#define PanTorqueMin -650 // -650 corresponds to 0% duty cylce for driving the motor full on in the other direction |

|||

#define pGain 0 // This is the Proportional coefficient, adjust this first |

|||

#define iGain 0 // This is the Integral coefficient, adjust this second |

|||

#define dGain 0 // This is the Derivative coefficient, adjust this last |

|||

signed int32 rise,fall,pulse_width; |

|||

int32 msecs=0; |

|||

signed int32 PanTarget = 0; |

|||

signed int32 PanActual = 0; |

|||

signed int32 PanError, PanErrorLastTime=0, PanIntegral, PanDerivative, PanTorque=0; |

|||

int16 value; |

|||

int i=0; |

|||

#int_ccp1 // This is the CCP capture interrupt, this allows you to use one pin (CCP1) to capture both |

|||

// the rising edge and falling edge of the servo PWM signal, which leaves the other CCP pin |

|||

// open for drving the servo motor |

|||

void isr() |

|||

{ |

|||

if (i==0) {output_high(PIN_A1); |

|||

rise = CCP_1; |

|||

setup_ccp1(CCP_CAPTURE_FE); |

|||

i=1;} |

|||

else if (i==1) {output_low(PIN_A1); |

|||

fall = CCP_1; |

|||

pulse_width = fall - rise; |

|||

setup_ccp1(CCP_CAPTURE_RE); |

|||

i=0;} |

|||

} |

|||

#INT_TIMER2 // designates that this is the routine to call when timer2 overflows |

|||

void Timer2isr() { |

|||

msecs++; // keep track of time |

|||

if ((msecs & 7) == 0) { // servo routine every 8ms is plenty. 125x/sec |

|||

output_high(PIN_B0); |

|||

PanTarget=pulse_width; |

|||

PanActual=read_adc(); |

|||

PanActual=25*PanActual; |

|||

PanError = PanTarget - PanActual; // position error |

|||

PanIntegral += PanError; |

|||

PanDerivative = PanError - PanErrorLastTime; |

|||

PanErrorLastTime = PanError; |

|||

PanTorque = pGain * PanError + iGain * PanIntegral + dGain * PanDerivative; |

|||

TorqueShifted=PanTorque>>16; |

|||

if (PanTorque < PanTorqueMin) PanTorque = PanTorqueMin; |

|||

if (PanTorque > PanTorqueMax) PanTorque = PanTorqueMax; |

|||

if (PanActual<PanTarget){ |

|||

output_low(PIN_C0); |

|||

set_pwm2_duty(PanTorque); |

|||

} |

|||

else if (PanActual>PanTarget){ |

|||

output_high(PIN_C0); |

|||

set_pwm2_duty(650 + PanTorque); |

|||

} |

|||

output_low(PIN_B0); |

|||

} |

|||

} |

|||

void main() { |

|||

setup_timer_2(T2_DIV_BY_4, 156, 16); // clock at 16KHz, interrupt every 4*25nS * 4 * 156 * 16 = 1.0mS |

|||

setup_timer_1(T1_INTERNAL); //start timer 1 |

|||

setup_adc_ports(AN0); // Enable analog inputs; This will read the ADC on pin AN0 |

|||

setup_adc(ADC_CLOCK_INTERNAL); |

|||

setup_ccp2(CCP_PWM); // PWM output on CCP1/RC2, pin 17 |

|||

setup_ccp1(CCP_CAPTURE_RE); |

|||

enable_interrupts(INT_CCP1); |

|||

enable_interrupts(INT_TIMER2); |

|||

enable_interrupts(GLOBAL); |

|||

//set_pwm2_duty(value); // h-bridge for pan motor from CCP2 (pin 16, RC1) to C0 (pin 16) |

|||

//output_high(PIN_C3); |

|||

while (TRUE) { |

|||

//This is useful for debugging using the RS-232 serial communication |

|||

printf("pulse width: %Lu Target: %Ld Actual: %Ld Torque: %Ld \r\n", pulse_width,PanTarget,PanActual,PanTorque); |

|||

} |

|||

} |

|||

</pre> |

|||

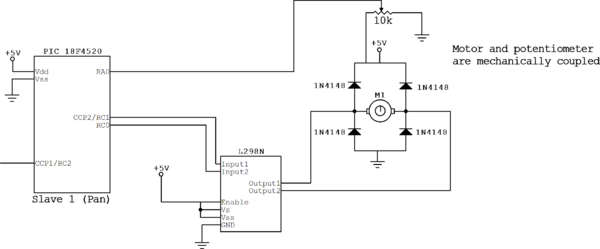

==Circuit== |

==Circuit== |

||

Revision as of 23:47, 19 March 2009

Code

#include <18f4520.h>

#device ADC=10 // set ADC to 10 bit accuracy

#fuses HS,NOLVP,NOWDT,NOPROTECT

#use delay(clock=40000000)

#use rs232(baud=19200, UART1) // hardware uart much better; uses RC6/TX and RC7/RX

#define PanTorqueMax 650 // 650 corresponds to 100% duty cycle for driving the motor full on in one dirction

#define PanTorqueMin -650 // -650 corresponds to 0% duty cylce for driving the motor full on in the other direction

#define pGain 0 // This is the Proportional coefficient, adjust this first

#define iGain 0 // This is the Integral coefficient, adjust this second

#define dGain 0 // This is the Derivative coefficient, adjust this last

signed int32 rise,fall,pulse_width;

int32 msecs=0;

signed int32 PanTarget = 0;

signed int32 PanActual = 0;

signed int32 PanError, PanErrorLastTime=0, PanIntegral, PanDerivative, PanTorque=0;

int16 value;

int i=0;

#int_ccp1 // This is the CCP capture interrupt, this allows you to use one pin (CCP1) to capture both

// the rising edge and falling edge of the servo PWM signal, which leaves the other CCP pin

// open for drving the servo motor

void isr()

{

if (i==0) {output_high(PIN_A1);

rise = CCP_1;

setup_ccp1(CCP_CAPTURE_FE);

i=1;}

else if (i==1) {output_low(PIN_A1);

fall = CCP_1;

pulse_width = fall - rise;

setup_ccp1(CCP_CAPTURE_RE);

i=0;}

}

#INT_TIMER2 // designates that this is the routine to call when timer2 overflows

void Timer2isr() {

msecs++; // keep track of time

if ((msecs & 7) == 0) { // servo routine every 8ms is plenty. 125x/sec

output_high(PIN_B0);

PanTarget=pulse_width;

PanActual=read_adc();

PanActual=25*PanActual;

PanError = PanTarget - PanActual; // position error

PanIntegral += PanError;

PanDerivative = PanError - PanErrorLastTime;

PanErrorLastTime = PanError;

PanTorque = pGain * PanError + iGain * PanIntegral + dGain * PanDerivative;

TorqueShifted=PanTorque>>16;

if (PanTorque < PanTorqueMin) PanTorque = PanTorqueMin;

if (PanTorque > PanTorqueMax) PanTorque = PanTorqueMax;

if (PanActual<PanTarget){

output_low(PIN_C0);

set_pwm2_duty(PanTorque);

}

else if (PanActual>PanTarget){

output_high(PIN_C0);

set_pwm2_duty(650 + PanTorque);

}

output_low(PIN_B0);

}

}

void main() {

setup_timer_2(T2_DIV_BY_4, 156, 16); // clock at 16KHz, interrupt every 4*25nS * 4 * 156 * 16 = 1.0mS

setup_timer_1(T1_INTERNAL); //start timer 1

setup_adc_ports(AN0); // Enable analog inputs; This will read the ADC on pin AN0

setup_adc(ADC_CLOCK_INTERNAL);

setup_ccp2(CCP_PWM); // PWM output on CCP1/RC2, pin 17

setup_ccp1(CCP_CAPTURE_RE);

enable_interrupts(INT_CCP1);

enable_interrupts(INT_TIMER2);

enable_interrupts(GLOBAL);

//set_pwm2_duty(value); // h-bridge for pan motor from CCP2 (pin 16, RC1) to C0 (pin 16)

//output_high(PIN_C3);

while (TRUE) {

//This is useful for debugging using the RS-232 serial communication

printf("pulse width: %Lu Target: %Ld Actual: %Ld Torque: %Ld \r\n", pulse_width,PanTarget,PanActual,PanTorque);

}

}