Difference between revisions of "Basketball"

From Mech

Jump to navigationJump to search| Line 44: | Line 44: | ||

== Code == |

== Code == |

||

== Results == |

== Results == |

||

In the end, the project ultimately succeeded -- baskets could be made. However, better tuning for the motor control and needs to be developed for more consistent results. |

In the end, the project ultimately succeeded -- baskets could be made. However, better tuning for the motor control and needs to be developed for more consistent results. |

||

Video |

|||

===Problems Encountered=== |

|||

*Attempting to integrate multiple pics and circuits onto one circuit board did not give good results. Ultimately, we had to use separate boards for each pic. We are not sure what the cause of this is -- perhaps it is noise. |

|||

*Motor control was an intense programming effort -- almost a project in its own right. Trying to combine the motor control and distance variation was difficult. Fly back diodes were used to prevent the H-Bridges from burning out. However, we still burned out many H-Bridges. |

|||

*The encoder chips also burned out. |

|||

*The PING sensor also burned out. |

|||

== Reflection == |

== Reflection == |

||

Revision as of 17:45, 18 March 2009

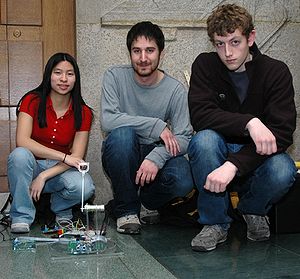

Team Members

- John Rula (Mechanical Engineering, Class of 2009)

- Alex Wojcicki (Mechanical Engineering, Class of 2009)

- Meredith Chow (Electrical Engineering, Class of 2010)

Introduction

A throwing arm propelled by a Pittman motor is mounted on a turntable and throws the ball into the "hoop." The hoop is wrapped in reflective tape and an IR emitter, receiver pair is used to sense where the IR is reflected most (the hoop with highly reflective tape). An ultrasonic sensor then pings the hoop for the distance of the hoop. With this information, the arm is able to "make a basket."

Mechanical Design

Components

| Part | Part No. | Qty | Vendor | Price (Total) |

|---|---|---|---|---|

| Pittman Motor | GM8712 | 1 | Lab | - |

| RC Servo Motor - Futaba | S3004 | 1 | Lab | - |

| Acrylic .25" Thick, 12"X 12" | 8560K354 | 1 | McMaster | $12.54 |

| Acrylic .25" Thick, 24"X 24" | 8560K357 | 1 | McMaster | $39.63 |

| Corrosion-Resistant Turntable | 6031K17 | 1 | McMaster | $2.42 |

| Fasteners | - | ~20 | Shop supply | - |

Drawings

Electrical Design

Components

| Part | Part No. | Qty | Vendor | Price (Total) |

|---|---|---|---|---|

| PICs | PIC18F4620 | 3 | Lab | - |

| Encoder | LS7083 | 1 | Lab | - |

| H-Bridge | L298N | 1 | Lab | - |

| Ping Ultrasonic Sensor | 28015 | 1 | Lab 5 supply | - |

| IR Emitter | QED123 | 1 | Lab | - |

| IR Phototransistor | LTR-4206E | 1 | Lab | - |

| Diodes | 1N4148 | 4 | Lab | - |

| Resistors | 47.5/150K | 2 | Lab | - |

Circuit Diagram

Code

Results

In the end, the project ultimately succeeded -- baskets could be made. However, better tuning for the motor control and needs to be developed for more consistent results.

Video

Problems Encountered

- Attempting to integrate multiple pics and circuits onto one circuit board did not give good results. Ultimately, we had to use separate boards for each pic. We are not sure what the cause of this is -- perhaps it is noise.

- Motor control was an intense programming effort -- almost a project in its own right. Trying to combine the motor control and distance variation was difficult. Fly back diodes were used to prevent the H-Bridges from burning out. However, we still burned out many H-Bridges.

- The encoder chips also burned out.

- The PING sensor also burned out.