Robot Drummer

Team Members

- Bobby By: Senior in Electrical Engineering

- Agatha Lee: Master Student in Biomedical Engineering

- Dan Niecestro: Senior in Mechanical Engineering

Overview

The goal of this project was to create a high speed motor controller which can receive commands and be modified through MATLAB, so that anyone could take a couple motors and a few dollars worth of hardware and implement accurate high-speed encoder-based feedback control. MATLAB sends commands via RS232 serial connection to a "master" PIC which in turn communicates with a number of "slave" PICs to initiate motor control. To demonstrate this, the Robot Drummer was created.

Mechanical Design

Mechanical Overview

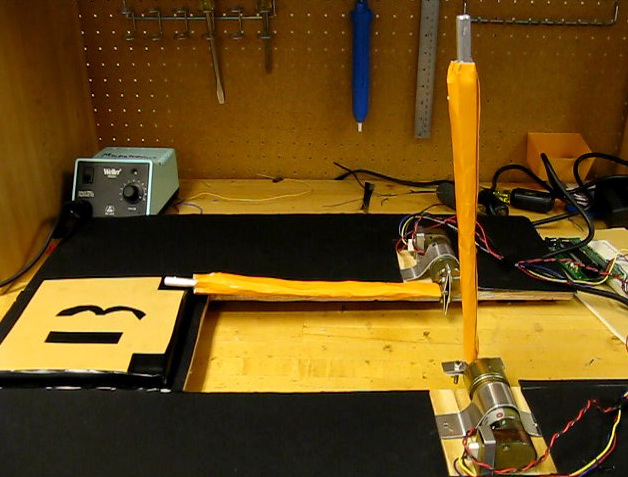

In this project, we were asked to demonstrate motor control of two separate motors running simultaneously. It was thought that a simple way to visually demonstrate motor control and be aesthetically pleasing was to make a small drum set.

This drum set consisted of a base, a drum pad and two drum sticks. All the parts were manufactured in the Northwestern machine shop, with materials supplied. The motors are removable and can be switched by loosening the brackets that hold them down. One of the main considerations was reusability of the motors and this setup allows easy removal or switching of motors from our device.

Base

The base was made in a U shape; this was done to allow the motors to hang over the insides and share the same drum pad, as seen above. Also, small legs were planted under the base so that when the motor rotated, the drumsticks would not hit the surface underneath. Both the legs and the main base was made of wood. Cardboard was placed over the base for aesthetic reasons

Securing Motor to Base

The motors were secured to the base using two brackets. The first bracket went around the circular part of our motor to hold the motor down and prevent side-to-side movement. Next, around the square part, a small, thin bracket was used to prevent the motor from moving up and down and slipping. Both brackets were set in place using screws to allow the bracket to open and close with ease. After securing it in place, the motors did not move at all and proved to be very secure.

Drum Pad

The drum pad is elevated off the base to allow the ends of the drumstick to hit it without hitting the base. Like the base, the drum pad is made of wood; it was then was covered in a thick poster/foam board material to dampen the sound since the metal hitting the wood was rather loud. This also gave the look of a drum pad. The number 13 was put on the pad represents our team number.

Drum Sticks

This was the most intensive part to make--there was a large number of trials and different ways of creating them. It was decided that the drum sticks should be made as light as possible to ensure that the motor could support it, therefore aluminum sheet metal was used. Basically, two L beams were made mirrored of each other and one hole was drilled for a screw on each side at the base of each beam. This was to connect to another small beam to go on the other side which will make a simple collet and a nice force fit on the shaft of the motor. To connect the two L beams together, rivets had to be used as spot welding aluminum is not very effective. Only three rivets were placed on the beam because a small circular rod of aluminum was added at the end of the beam. The beam had to open up and the rod was place in the middle, where two holes were drilled to prevent the rod from moving. Lastly, we wrapped it in a yellow glossy paper to make them look more like drumsticks; however, these coverings are not exactly round because it had to attach to the beam itself, which isn’t round. The result showed that it created a very nice force fit which had very little to no slipping on the motor shaft.

Electrical Design

Component List

| Part | Part No. | Qty |

|---|---|---|

| PIC18F4520 Prototyping Board | --- | 3 |

| Microchip 8-bit PIC Microcontroller | PIC18F4520 | 1 |

| Microchip 8-bit PIC Microcontroller | PIC18F4431 | 2 |

| RS232 Cable | TTL-232R | 1 |

| Pittman Motor with Encoder | GM8224 | 2 |

| Hex Inverter Chip | SN74HC04 | 1 |

| H-Bridge Chip | L293D | 2 |

| 10K Resistor | --- | 2 |

Setup

All of the components, except the Pittman motors, were powered with 5V DC. The Pittman motors were powered with 12V DC.

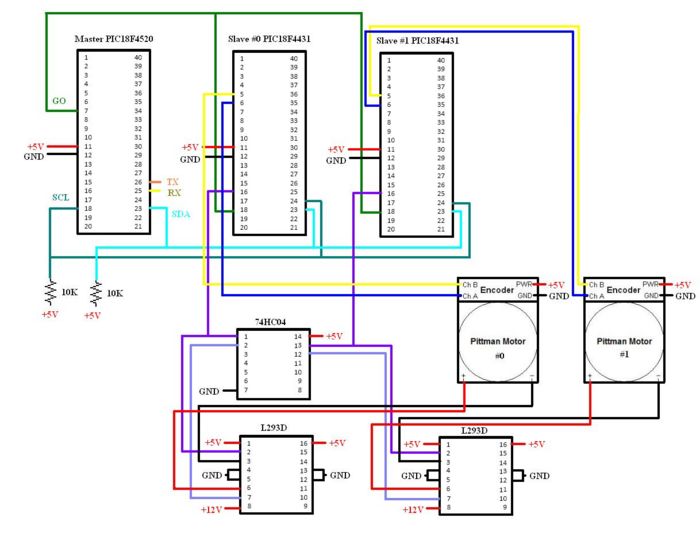

PICs

Two kinds of PICs were used: one "master" 18F4520 and two "slaves" 18F4431. The 18F4431 has a built in quadrature encoder, which makes it convenient for encoder-based motor control. This eliminates the need of a counter chip, such as a LS7083 used in the original I2C motor control circuit. The PICs communicate via I2C. I2C communication requires 2 connections: clock(SCL) and data(SDA). The SCL line and SDA line were connected from pin 18 and pin 23 of the master PIC to pin 24 and pin 23 of all slave PICs, respectively. Note that the SCL and SDA lines need a 10 Kohm pull-up resistor. There is also a "Go" signal from pin 7 of the master to pin 18 of the slave PICs.

The TTL-232R has six color-coded wires, but only 3 were required with this project. The black GROUND wire was connected to PIC ground, the orange Tx wire was connected to pin 26 of the master PIC and the yellow Rx wire was connected to pin 25 of the master PIC.

H-Bridge

The slave PICs send an individual PWM to a L293D H-bridge. Th PWM duty determines the speed of each motor. The motor is at rest at a 50% duty cycle and is at its maximum speed at 0 and 100% duty cycles. Pin 16 of the slave PIC was connected to pin 2 of a L293D. The H-bridge needed to be powered with +12V on pin 8 (power supply to the motor), +5V on pin 1 and grounded on pins 4 and 5. Pin 16 was also powered with +5V and pins 12 and 13 were grounded to minimize noise. Note that the L293D is rated for 1A of output current only. You may want to use a different H-bridge if higher current capacity is required.

Hex Inverter

Pin 16 of the slave PICs was also run through the 74HC04 hex inverter chip (pin 1 or pin 13). The output of the hex inverter (pin 2 or pin 12) was sent to pin 7 of L293D. Pin 14 was powered with +5V and pin 7 was grounded.

Pittman Motors

The positive end and negative end of the Pittman motor were connected to pin 6 and pin 3 of the H-bridge, respectively. Encoder A of the Pittman motor was connected to pin 6 of the slave PICs, while encoder B was connected to pin 5.

Schematic

Programming

Overview

Three sets of code were required for our project: the MATLAB code, C code for the master PIC, and C code for the slave PICs. The MATLAB code sends commands to the master PIC. The master PIC code read all the serial communication from MATLAB and converted it into appropriate I2C commands for the slave PICs, which were completely dedicated to motor control and encoding.

Code

Robot_Drummer_Matlab.zip

Robot_Drummer_MotorControllerFunctions.c

Robot_Drummer_Master.c

Robot_Drummer_Slave.c

Matlab

Robot_Drummer_Matlab.zip contains all the MATLAB functions used in our implementation, as well as two sample code files to demonstrate motor control. The following table outlines the commands that can be sent from MATLAB. (The MATLAB functions were originally written by Matt Turpin in his I2C Motor Controller project, modified very slightly for our controller implementation.)

| Matlab Function | Purpose | Command Format | Example | Example's Outcome |

|---|---|---|---|---|

| MotorControllerConnect.m | Enables communication between Matlab and the master PIC | serial object = MotorControllerConnect(serial port number) | s = MotorControllerConnect(6) | Will connect the master and Matlab through COM port 6 |

| mc_resetpos.m | Resets the current position to zero | mc_reset_pos(device,serial object) | mc_reset_pos(0,s) | Will reset slave #0 motor's current position to zero |

| set_mc_position.m | Sets the desired position | set_mc_position(position,device,serial object) | set_mc_position(5000,0,s) | Will set slave #0 motor's current position to 5000 |

| mc_get_position.m | Gets the current position | position = mc_get_position(device,serial object) | position = mc_get_position(0,s) | Will get slave #0 motor's current position |

Master

There are two files related to the master PIC. Robot_Drummer_Master.c is the file that needs to be programmed onto the master PIC. Robot_Drummer_MotorControllerFunctions.c should be put in the same directory as Robot_Drummer_Master.c. Refer to this datasheet for more details on the master PIC functions.

The master PIC can be used in two ways:

1) Receive commands from Matlab through the RS232 cable and then send it to a slave PIC

2) Directly send commands to a slave PIC without having MATLAB involved

When the master PIC receives data through the serial connection to the PC, the appropriate function in Robot_Drummer_MotorController.c is called; the command is then relayed to the slave with the appropriate address via I2C. If data was requested, the master receives the requested data from the slave and sends it back to Matlab.

Slave

Each slave PIC is programmed with Robot_Drummer_Slave.c. Here, we have assigned the I2C address explicitly in the code, but you may also connect pins B4, B5, E2, E1 as described in the I2C Motor Controller datasheet to assign the address to each slave.

The following table shows a few preset I2C addresses. The device numbers are used in the Matlab commands, while the Hex addresses are the ones defined in the slave code. There are 16 preset addresses in the MATLAB device lookup table. Refer to the datasheet for the full table of preset slave addresses.

| Device Number | Hex I2C Address |

|---|---|

| 0 | 80 |

| 1 | 82 |

| 2 | 84 |

Quad Encoder

We used the PIC 18F4431 quadrature encoder interface (QEI), for which registers were not defined in the CCS .h file; hence the registers were defined and modified explicitly in the slave code.

#byte QEICON= 0xFB6 // Quadrature Encoder Interface control register int16 POSCNT; // Position Count register (16 bit) #byte POSCNT = 0xF66 #byte POSCNTH = 0xF67 #byte POSCNTL = 0xF66 int16 MAXCNT; // Can set POSCNT to reset when POSCNT=MAXCNT #byte MAXCNT = 0xF64 #byte MAXCNTH = 0xF65 #byte MAXCNTL = 0xF64

The Pittman motor encoder has a resolution of 39000 counts per revolution at 4x encoding. It would be desirable to be able to set any angle within 720 degrees (-360 to +360), or 78000 encoder counts at 4x encoding. However, since POSCNT is only a 16-bit integer, the count cannot exceed 65535. You may be able to count a full 720 degrees by keeping track of position counter overflow/underflow (bit 7 of QEICON). Instead, we implemented angle control of approximately -180 to +360 degrees, which was sufficient for our Robot Drummer. The QEI mode was set to position mode, 4x encoding, position counter reset on matching MAXCNT.

QEICON = 10011000; //Velocity mode disabled, 4x update mode, reset on POSCNT=MAXCNT MAXCNT = 59000; //count 540 degrees max POSCNT = 20000; //start at 0 degrees

I2C

We had a great deal of trouble trying to get I2C communication between the 18F4431 and the 18F4520 to work, all of which was resolved by simply including this register definition in the slave code:

#byte SSPCON = 0xFC6

This is required possibly due to the fact that the 4431 uses an SSP module instead of MSSP like the 4520 and most other 18F PICs, and has one SSP control register instead of two (refer to this PIC forum thread).

Control

Each slave PIC is programmed with a PD control algorithm with hard-coded control gains to drive the motor to the desired position. The code may be easily modified to receive gain values from the master to tune the controller. The error between the target and actual position is calculated, and the derivative term approximated by finding the difference between the errors of the current and previous iteration of the status update. The sum of the proportional and derivative error terms multiplied by the gain is used to modify the PWM duty to adjust the position of the motor. When the error is zero, the duty is at 50% and the motor stops. It was noted that there is a "dead band" of duty values near 50% at which the motor will stop even though the motor has not reached the target position. This band is relatively narrow when the motor is powered at +12V but gets wider as the voltage input decreases.

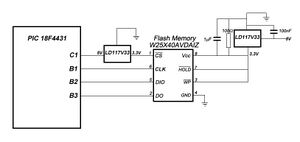

Datalogging to Flash Memory

One of the original objectives of this project was to store the position data onto a flash memory chip during PID control to get a high resolution profile of the motor movement to let the user to better tune the motor controller. Unfortunately, this part of the project was left unfinished.

Overview

The flash memory chip W25X40AVDAIZ-ND uses SPI communication to store and read data. The 18F4431 uses the SSP module for both SPI and I2C communication; since the hardware SPI pins are used by I2C communication with the master we attempted to use software SPI. It may be possible to reassign the SPI pins to other I/O pins and use the software SPI functions available in CCS, as described here, but it may be necessary change the SSPCON registers to switch between SPI and I2C modes.

Flash Memory Circuit

The flash memory chip takes 3.3V input, although transient pin voltage may go up to +5V. We used a 3.3V voltage regulator to produce a 3.3V supply from 5V. It appeared that the quality of the DO signal from the flash chip was sensitive to the RC values on the output of the voltage regulator. There may be better values of resistor/capacitor for the circuit than the ones indicated in the circuit diagram. The /HOLD and /WP pins are tied high to disable the hold and write protect functions; they may be connected to PIC I/O pins if those functions are desired. The /CS pin is connected to PIC pin C1 through another 3.3V voltage regulator, as the pin would be held high for an extended length of time. The Clock, Data In and Data Out pins are connected to Pins B1, B2 and B3 of the PIC.

SPI Communication

SPI operates full duplex, so data can be sent and received simultaneously on two separate data lines. Each byte of data is sent MSB (bit 7) first.

#include <18f4431.h>

#fuses HS,NOLVP,NOWDT,NOPROTECT

#use delay(clock=40000000)

#define SPI_CS PIN_C1 //Chip select

#define SPI_CLK PIN_B1 //Clock

#define SPI_DO PIN_B2 //Data Out - connect to DIO of flash chip

#define SPI_DI PIN_B3 //Data In - connect to DO of flash chip

#use rs232(baud=19200, UART1) // hardware UART; uses RC6/TX and RC7/RX

int i=0;

int data=0;

int32 address=0;

byte d_in=0b00000000;

byte d_out=0b00000000;

void setup()

{

set_tris_b(248); //Set Pins B1-B2 as outputs, B3 as input

output_high(SPI_CS); //Chip not selected

output_low(SPI_CLK); //Mode 0 - clock is low during standby

output_low(SPI_DO);

address=0;

}

int8 xfer_spi(int8 data)

{

d_in=data;

// Loop through all the bits, 7...0

for(i= 0; i < 8; i++)

{

output_bit(SPI_DO, shift_left(&d_in, 1, 0));

shift_left(&d_out, 1, input(SPI_DI));

output_high(SPI_CLK); // flash input data latched on rising edge

delay_us(2);

output_low(SPI_CLK); // flash output data latched on falling edge

}

output_low(SPI_DO);

return d_out;

}

The xfer_spi function is modified from this bit banging sample code. This function can be used to send or receive a byte of data. The flash memory chip has an instruction set of 15 basic instructions to read, program, erase data etc. Refer to the datasheet for the full instruction set.

To test whether we can read from the chip, you can send an instruction to get the manufacturer and device ID (0xEF12).

void main()

{

int data1=0;

int data2=0;

setup();

address=0;

// read Manufacturer/Device ID

output_low(SPI_CS); //drive CS pin low to enable

xfer_spi(0x90); //instruction to read manufacturer/device ID

xfer_spi((int8)(address)); //send 24-bit address=0x000000

xfer_spi((int8)(address>>8));

xfer_spi((int8)(address>>16));

data1 = xfer_spi(0x00); //get manufacturer ID

data2 = xfer_spi(0x00); //get device ID

delay_us(10);

output_high(SPI_CS); //CS pin high to deselect chip

printf("%u\n\r %u\n\r", data1, data2);

}

We were able to read the manufacturer and device data using this code. Unfortunately, we didn't have time to confirm that we can write data to flash and read it back, or to integrate flash data logging into our project. If integrated into the slave code, the 16-bit position counter would be saved to flash every time updatestatus() was called, which is every 500us.

Results

Objectives Met

Despite the problems we encountered early on in the project, overall we are pleased with the progress we've made in a relatively short amount of time. We believe this project will be of great use to others. We were able to meet the following objectives:

- Make it easy for anyone to do high-speed encoder-based feedback control of brushed DC motors cheaply.

- The master PIC is consistently able to receive commands from Matlab using the RS232 cable.

- The master PIC is consistently able to communicate the commands back to the slave PICs using I2C.

- Learn about and take advantage of the 18F4431's built-in quad encoder module.

- The slave PICs implement feedback PD control.

- Upon request, data can be sent from the slave PICs back to MATLAB.

Reflections

Initially we encountered a lot of trouble with communication of the different units. For those trying to recreate this project, it may be useful to build each part separately and then combine them. We found the debugging strategy below to be useful.

Debuggging Strategy

Test RS232

In order to test the RS232, connect the RS232 cable to the appropriate pins of the master PIC (see Electrical Design). To determine whether the master PIC can receive data from the RS232, send a desired position from Matlab and turn on some LEDs (e.g. display the position in the LEDs) in the master PIC code. The following code in the master PIC's Robot_Drummer_MotorControllerFunctions.c will do this.

void set_mc_pos(int device, int32 position)

{

int* output[5] = {0,0,0,0,0};

int ii;

output_d(position);

output[0] = 2;

for(ii=0;ii<2;ii++)

{

output[ii+1] = (int8)(position>>(8*(ii)));

}

mc_transmit(device,output);

}

Test I2C

Commands can be sent directly to a slave PIC from the master PIC. For example, the following code can be used in the main loop to send a desired position.

set_mc_pos(0x80,5000); mc_go();

Look at the I2C lines on the oscilloscope and make sure that the slave is acknowledging when the master is sending the address, etc. It may also be useful to turn on LEDs to see that the master is transmitting data and/or the slave is receiving data.

Test Motor Control

In the slave code, instead of waiting to receive commands from the master, manually set the target position in the main loop. This way, you can tweak the code directly and see if the motor control is working.

Other Problems

- The L293D H-bridge heated up and eventually burnt out a couple of times during testing.

- Occasionally, the drum sticks tried to reach their position by making a complete 360, but this was not possible due to the drum. This would cause internal problems in the motor. The 360 spin may be due to overflow/underflow of the position counter, which is a bug in the code that should be fixed.

- The drum sticks would sometime fall from its position due to gravity.

Future Work

There are many options that could be researched and developed to make this project better.

- Implement flash memory data logging to get high resolution position data during motor control.

- Improve the motor control algorithm. In addition to the position control that is available, implement velocity control. The 18F4431 QEI module can be operated in velocity mode, which may be helpful. The 18F4431 also has a Power Control PWM module which might be useful in motor control applications.

See Also

References

PIC 18F4431 Datasheet

I2C Communication between PICs

SPI Communication between PICs

More info on SPI

Serial Communication by Bit Banging